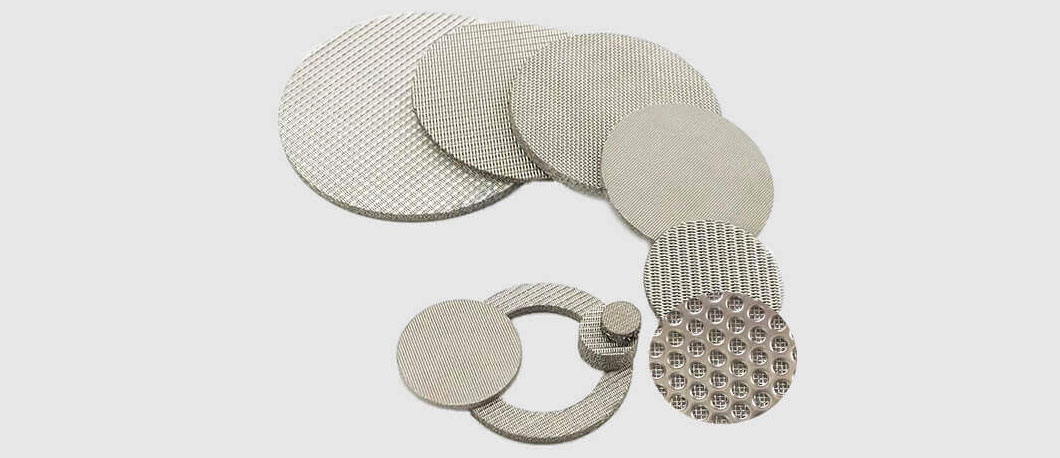

In the sophisticated realm of filtration, Wire Mesh Filter Pads stand out as essential components designed to meet the rigorous demands of various industrial processes. Crafted from woven or welded wire mesh, these filter pads are engineered to provide optimal filtration efficiency, durability, and adaptability. This blog post aims to explore the characteristics of Wire Mesh Filter Pads, their wide-ranging applications, and the significant advantages they bring to filtration systems.

Key Features of Wire Mesh Filter Pads

Wire Mesh Filter Pads are celebrated for a host of features that underscore their utility:

- Customisable Filtration Grades: Available in various mesh sizes and materials, these filter pads can be tailored to specific filtration requirements, from coarse to fine filtration.

- High Durability: Constructed from materials such as stainless steel, these pads withstand harsh conditions, including high temperatures and corrosive environments.

- Versatility: Suitable for liquid, air, and gas filtration, their versatility makes them indispensable in numerous applications.

- Ease of Maintenance: Designed for easy cleaning and maintenance, Wire Mesh Filter Pads can be reused, offering cost-efficiency over time.

Diverse Applications Across Sectors

The utility of Wire Mesh Filter Pads spans a multitude of industries, evidencing their adaptability:

- Chemical Processing: Utilized in the filtration of chemicals and solvents to remove particulate contaminants and ensure product purity.

- Oil and Gas: Critical in the separation and filtration processes of oil and gas production, where they help remove impurities and safeguard equipment.

- Pharmaceuticals: Employed in the manufacture of pharmaceutical products to ensure the removal of particulate matter, contributing to the safety and efficacy of medicines.

- Food and Beverage: Used in the filtration of edible oils, beverages, and other food products, they play a key role in maintaining quality and compliance with health standards.

- Water Treatment: Integral to water purification systems, filtering out sediments, contaminants, and harmful organisms to ensure water safety.

The Advantages of Opting for Wire Mesh Filter Pads

Choosing Wire Mesh Filter Pads for filtration systems offers several compelling benefits:

- Efficiency: Their precise construction allows for optimal filtration performance, effectively separating and removing unwanted particles from fluids or gases.

- Longevity: The robust materials used in their manufacture, such as stainless steel, ensure a long service life, reducing the need for frequent replacements.

- Cost-Effectiveness: Given their durability and reusability, these filter pads present a cost-effective solution, minimizing operational and maintenance expenses.

- Customisation: The ability to tailor the mesh size and material to specific filtration needs ensures that processes are as efficient and effective as possible.

Wire Mesh Filter Pads by Indo German Wire Screen Co. are integral to the success of modern filtration systems, offering a blend of efficiency, durability, and versatility. Their wide-ranging applications across industries underscore their adaptability and critical role in maintaining quality, safety, and operational integrity. By leveraging the capabilities of Wire Mesh Filter Pads, industries can achieve superior filtration performance, ensuring that products and processes meet the highest standards of purity and quality.