Our goal is to provide our customers with a seamless experience at every touch point.

Fabrication Capabilities

Manufacture of Wire Mesh, Wire Cloth and Packaging Types

We deploy numerous efficient and effective methods – such as weaving, welding, netting, or knitting that are utilised to process metallic wires into wire mesh. Welded wire mesh is formed via automated CNC welding machines as horizontal wires are constantly fed in parallel rows into the machine directly from the coil. Vertical wires are straightened, cut, and laid onto the horizontal wires for spot welding operations. By this method, a flat and rigid panel with square, rectangular, or diamond-shaped meshes is manufactured. A shear cuts the mesh panel once it reaches its specified length. At that juncture, a transporting device extracts the final products from the welding line and stacks them for the following transportations.Our numerous diameter and wire spacing configurations allow great panel customization to accommodate any need.

Wire cloth is made on weaving machines as the longitudinal warp wires run continuously from the back of the machine to the front side. A machine clutches the warp wires in place. Certain of these wires are on the other hand raised or dropped by a mechanism, creating an opening in the transverse direction. A shuttle – with another wire, called weft wire – is “shot” through one opening, returned through the following one, and so on. In this way, the weft wire is woven through the warp wires. Both types of wires interlace with each other at specific angles to form the wire cloth. Wire mesh or wire nettings are manufactured via chain link machines, which loop different wires into one another according to a regular pattern. Whether you choose to call it wire cloth or wire mesh, this durable yet extraordinarily versatile material can be used for a variety of protection and support manufacturing applications.

Custom Wire Cloth Fabrication Services

Indo German Wire Screen Co. is your one stop solution for an wide-ranging selection of stock wire-cloth products for companies across a broad spectrum of industries, including onshore, refining, and offshore drilling, parks and zoos, and mining. We have the competence to provide custom fabricated wire mesh/cloth solutions to make the specialized product your business wants. We will develop and fabricate a product with the ideal shape, mesh size, mesh count and/or weave type for virtually any application.

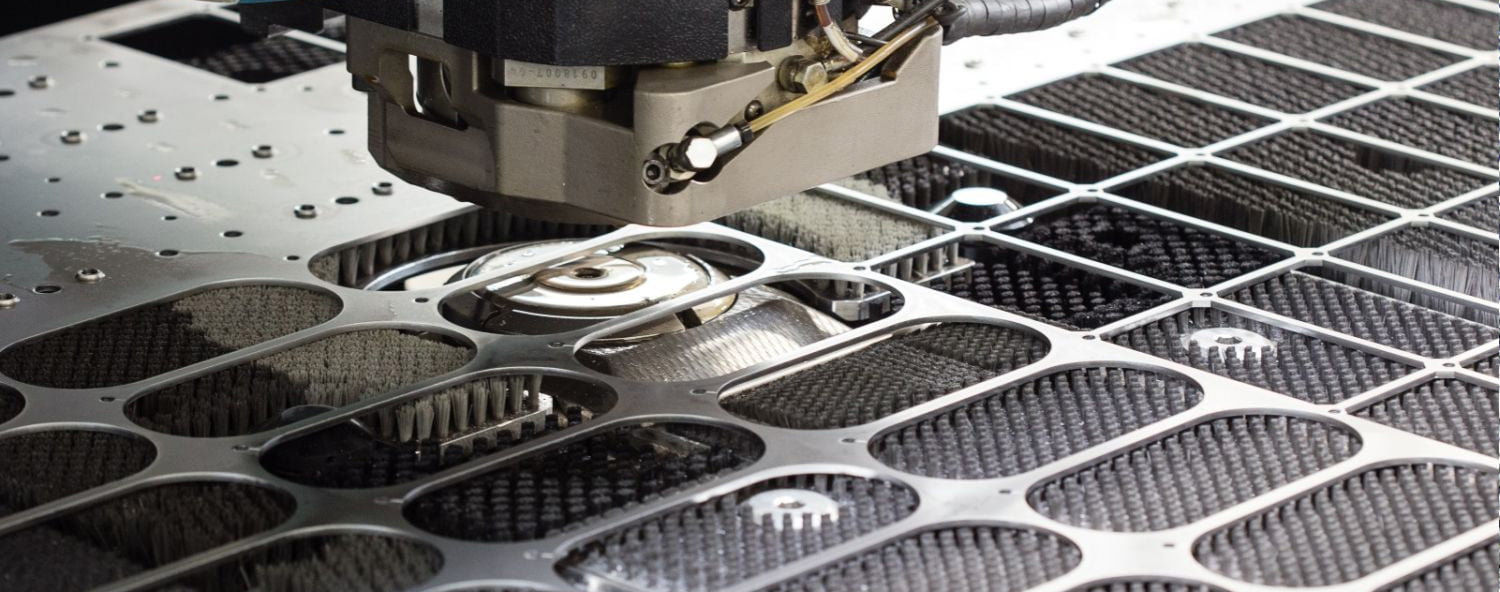

Wire Mesh Fabrication Services

- Cutting and shearing

- Rolling and straightening

- Welding

- Forming

- Slitting

- Edging

- Stamping and notching

Wire cloth is made on weaving machines as the longitudinal warp wires run continuously from the back of the machine to the front side. A machine clutches the warp wires in place. Certain of these wires are on the other hand raised or dropped by a mechanism, creating an opening in the transverse direction. A shuttle – with another wire, called weft wire – is “shot” through one opening, returned through the following one, and so on. In this way, the weft wire is woven through the warp wires. Both types of wires interlace with each other at specific angles to form the wire cloth. Wire mesh or wire nettings are manufactured via chain link machines, which loop different wires into one another according to a regular pattern. Whether you choose to call it wire cloth or wire mesh, this durable yet extraordinarily versatile material can be used for a variety of protection and support manufacturing applications.

Customizable Wire Cloth Products and Materials

Our custom wire mesh products include woven, welded, space cloth, market grade wire mesh, refinery grade wire, galvanized hardware cloth, filter cloth, mill grade wire mesh, bolting cloth, and sintered mesh. Our metal materials include aluminium, carbon steel, stainless steel, galvanized steel, and exotic nickel alloys such as the Monel series.

Custom Wire Cloth Fabrication for Numerous Applications

Wire mesh infill panels, Wire Cloth Fabrication Infill Panels, Temporary pipeline strainers, Wire mesh baskets, Extruder screens, Wire strainer baskets, Fabricated wire mesh, Wire mesh cylinders, Wire mesh discs, Wire mesh filters, Catalyst Support, Wire mesh trays, Outlet Collector, Cone strainers, Wire Cloth Suction Screens, Cup screens, Custom Wire Basket, Wire cloth fabrication, Fabricated wire mesh products, and many more.

Our fabrication workshop features the up-to-date equipment — such as shears, saws, rollers and welding machinery for accommodation just about any type of custom wire-cloth fabrication project. Our modern facility includes a fully equipped, state-of-the-art fabrication workshop where we can change any stock wire product into the customized solution that will meet your exact requirements.

Indo German Wire Screen Co. has been providing quick, durable, and reliable wire cloth fabrications. Please Contact Indo German Wire Screen Co. at 91 – 9820291268 or submit Enquiry Form for more information about our custom wire-mesh fabrication services and to get a no-obligation project quote today.