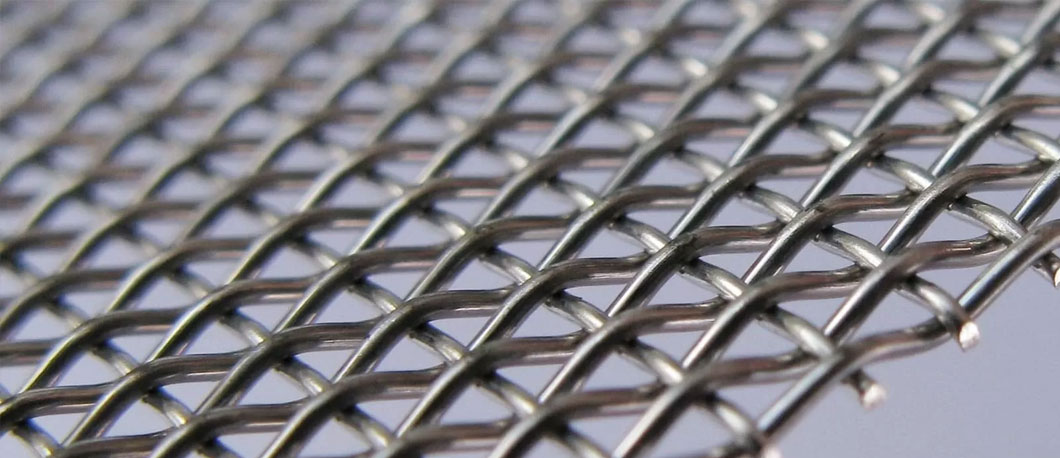

Hastelloy C276 wire mesh is a top choice in the chemical industry due to its unmatched corrosion resistance, strength, and durability. This nickel-based alloy is engineered to withstand the harshest environments, making it indispensable for various applications such as filtration, heat exchangers, and chemical storage tanks. Below, we explore the key reasons for its preference, its applications, and the unique advantages it offers.

Key Features of Hastelloy C276 Wire Mesh

- Exceptional Corrosion Resistance

Hastelloy C276 is known for its ability to resist a broad range of aggressive chemicals. It offers superior resistance to:

- Wet chlorine gas.

- Hypochlorite and chlorine dioxide solutions.

- Acids, including sulfuric, hydrochloric, and nitric acids.

- Ferric and cupric chlorides.

This high corrosion resistance ensures longevity in extreme environments where traditional metals fail.

- Pitting and Crevice Corrosion Resistance

The nickel, molybdenum, and chromium composition of Hastelloy C276 makes it highly resistant to localized corrosion, including pitting and crevice corrosion. This is critical for equipment used in chemical processing where exposure to corrosive substances is constant.

- High-Temperature Capability

Hastelloy C276 wire mesh can operate efficiently in high-temperature environments, withstanding temperatures up to 1900°F (1037°C). This makes it suitable for heat-intensive chemical reactions and processing systems.

- Stress Corrosion Cracking Resistance

The alloy exhibits excellent resistance to stress corrosion cracking, a common concern in chemical plants. This ensures structural integrity and reduces the risk of equipment failure.

- Weldability and Fabrication

Hastelloy C276 can be welded and fabricated with ease, without compromising its corrosion resistance. This allows for the creation of complex filtration systems and custom components for specific industrial needs.

Applications of Hastelloy C276 Wire Mesh in Chemical Industries

- Chemical Filtration Systems

Hastelloy C276 wire mesh is widely used in filtration systems to separate and purify corrosive liquids and gases. Its ability to withstand aggressive chemicals ensures consistent performance over time.

- Heat Exchangers

The high-temperature capability and corrosion resistance of Hastelloy C276 make it ideal for heat exchangers handling corrosive fluids. It ensures efficient heat transfer without degradation.

- Scrubbers and Gas Cleaners

Hastelloy C276 is used in scrubbers for cleaning gases in chemical plants. Its resistance to harsh chemicals and acidic environments ensures long-lasting performance.

- Chemical Storage Tanks

The alloy is often used as liners or internal components in tanks that store corrosive chemicals, ensuring the tanks remain functional and leak-free.

- Pollution Control Systems

Hastelloy C276 wire mesh plays a critical role in controlling pollution, particularly in flue gas desulfurization systems, due to its ability to resist sulfur-containing gases and acidic condensates.

Benefits of Using Hastelloy C276 Wire Mesh

- Longevity and Cost-Effectiveness

While the initial cost of Hastelloy C276 may be higher than other materials, its long lifespan and low maintenance requirements make it a cost-effective choice for chemical industries. Reduced downtime and fewer replacements contribute to significant cost savings.

- High Strength and Durability

Hastelloy C276 offers excellent mechanical properties, making it suitable for applications involving high stress and pressure. Its strength ensures reliable performance under challenging conditions.

- Versatility in Fabrication

The alloy’s weldability and formability allow it to be fabricated into various shapes and sizes, including rolls, discs, and custom designs. This versatility meets the diverse needs of chemical processing applications.

- Environmental Compatibility

The corrosion-resistant properties of Hastelloy C276 reduce the risk of chemical leaks and environmental contamination, making it a safer and more sustainable option for the chemical industry.

Chemical Composition of Hastelloy C276

| Element | Percentage |

| Nickel (Ni) | Balance |

| Molybdenum (Mo) | 15.0 – 17.0 |

| Chromium (Cr) | 14.5 – 16.5 |

| Iron (Fe) | 4.0 – 7.0 |

| Tungsten (W) | 3.0 – 4.5 |

| Cobalt (Co) | 2.5 max |

| Carbon (C) | 0.02 max |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 0.08 max |

| Phosphorus (P) | 0.03 max |

| Sulfur (S) | 0.03 max |

Why Choose IG Wire Screen for Hastelloy C276 Wire Mesh?

As a trusted manufacturer and supplier of wire mesh products in Mumbai, India, IG Wire Screen provides top-quality Hastelloy C276 wire mesh for various industrial applications. With customizable solutions, competitive pricing, and a commitment to excellence, IG Wire Screen ensures that your chemical processing needs are met with precision and reliability.

Explore our range of Hastelloy wire mesh products on our products page or contact us directly for more information.

Unlock the Potential of Hastelloy C276 Wire Mesh in Chemical Industries

Harness the unmatched properties of Hastelloy C276 wire mesh for your chemical processing needs. Its exceptional corrosion resistance, high strength, and versatility make it the ultimate choice for demanding environments. Contact IG Wire Screen today to discover how our Hastelloy wire mesh can elevate your operations.