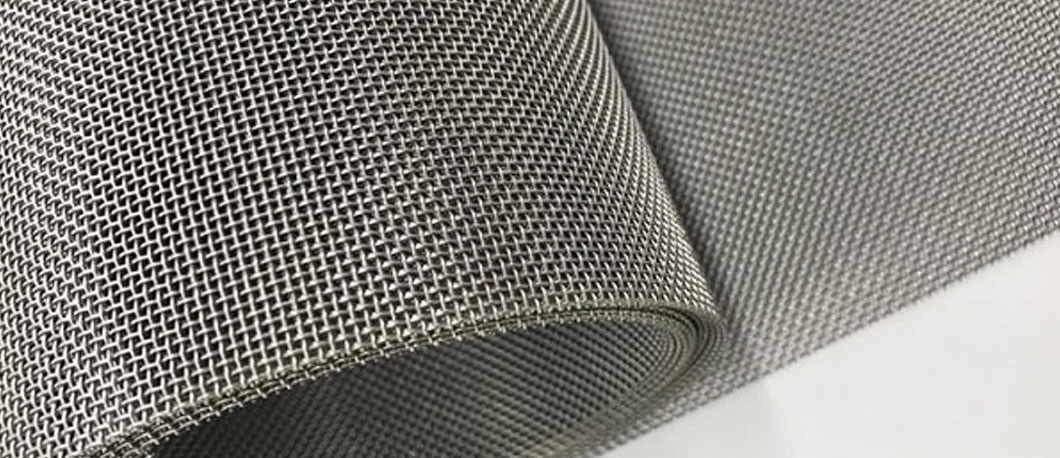

Monel 400 wire mesh, a nickel-copper alloy, stands out as an indispensable material in aerospace applications, thanks to its high strength, superior corrosion resistance, and exceptional heat resistance. This versatile alloy—comprised primarily of nickel and copper—is not only durable but also excels in environments that demand reliability and longevity. Monel 400 wire mesh finds widespread use in aerospace, marine, chemical, and industrial sectors, cementing its reputation as a premium choice for critical applications.

For more information, visit our Wire Mesh and Monel 400 Wire Mesh pages.

Why Monel 400 Wire Mesh is Ideal for Aerospace Applications

Exceptional Corrosion Resistance

Monel 400 offers outstanding corrosion resistance, even in harsh environments such as seawater, acidic, and alkaline conditions. This property ensures that the material performs reliably in aerospace components exposed to extreme atmospheric and chemical conditions.

High Strength and Durability

With a yield strength of 172-345 MPa (25-50 ksi), Monel 400 wire mesh provides exceptional mechanical performance. Its robust structure ensures resistance to mechanical stress and wear in demanding aerospace environments.

Heat Resistance

Monel 400 withstands elevated temperatures up to 1,000°F, making it suitable for high-temperature applications in aerospace engines and heat exchangers.

Chemical Compatibility

This alloy resists various chemicals, including hydrochloric acid and sulfuric acid, ensuring its functionality in fuel systems, chemical storage, and propulsion components.

Key Properties of Monel 400 Wire Mesh

| Property | Details |

| Composition | ~67% Nickel, ~31% Copper |

| Corrosion Resistance | Excellent in acidic and alkaline environments |

| Yield Strength | 172-345 MPa (25-50 ksi) |

| Operating Temperature | Up to 1,000°F |

| Non-Magnetic Properties | Non-magnetic above room temperature |

Applications of Monel 400 Wire Mesh

Aerospace Industry

- Heat Exchangers: Monel 400 wire mesh is used in aerospace heat exchangers due to its ability to withstand high temperatures and corrosive gases.

- Fuel Systems: Its chemical resistance makes it ideal for fuel storage and transfer systems.

- Structural Components: Ensures durability in critical aerospace assemblies exposed to mechanical stress and environmental factors.

Marine Industry

Monel 400 is extensively utilized in marine applications such as naval shipyards, offshore platforms, and marine technologies, where resistance to saltwater corrosion is crucial.

Chemical and Hydrocarbon Processing

- Used in chemical plants for filtration, separation, and protection against corrosive elements.

- Applicable in hydrocarbon processing for distillation and separation tasks.

Industrial Applications

- Valves and Pumps: Monel 400’s durability ensures reliability in high-pressure and corrosive environments.

- Heat Exchangers: Offers excellent thermal stability and resistance to scaling.

For more details, visit our Our Products page.

Types and Specifications of Monel 400 Wire Mesh

Common Mesh Sizes

| Mesh Count | Wire Diameter | Aperture Size | Open Area |

| 8 x 8 | 0.0280 in | 0.0970 in | 60.20% |

| 20 x 20 | 0.0160 in | 0.0340 in | 46.20% |

| 60 x 60 | 0.0075 in | 0.0090 in | 30.50% |

| 100 x 100 | 0.0045 in | 0.0060 in | 30.30% |

Roll Dimensions

- Width: Up to 1.5 m

- Length: 30 m, 50 m, 100 m

- Customization: Custom sizes and specifications available.

Comparison with Other Alloys

Monel 400 vs. Stainless Steel

- Corrosion Resistance: Monel 400 surpasses stainless steel in marine and chemical environments.

- Strength: Comparable strength; however, Monel 400 performs better in high-temperature conditions.

- Cost: Monel 400 is more expensive but provides superior longevity and performance.

Monel 400 vs. Aluminum

- Durability: Monel 400 is more durable and resistant to corrosion than aluminum.

- Weight: Aluminum is lighter, making it suitable for weight-sensitive applications.

Maintenance and Longevity of Monel 400 Wire Mesh

To ensure the longevity and optimal performance of Monel 400 wire mesh:

- Clean Regularly: Use non-corrosive cleaning agents to prevent buildup.

- Inspect Periodically: Check for signs of wear and address issues promptly.

- Protect Against Mechanical Stress: Avoid excessive strain to maintain structural integrity.

Enhance Your Aerospace Projects with Monel 400 Wire Mesh

Monel 400 wire mesh is the ultimate solution for aerospace applications requiring high strength, corrosion resistance, and heat stability. Its unmatched properties and adaptability make it the preferred choice for critical systems and components.

For more details, visit: