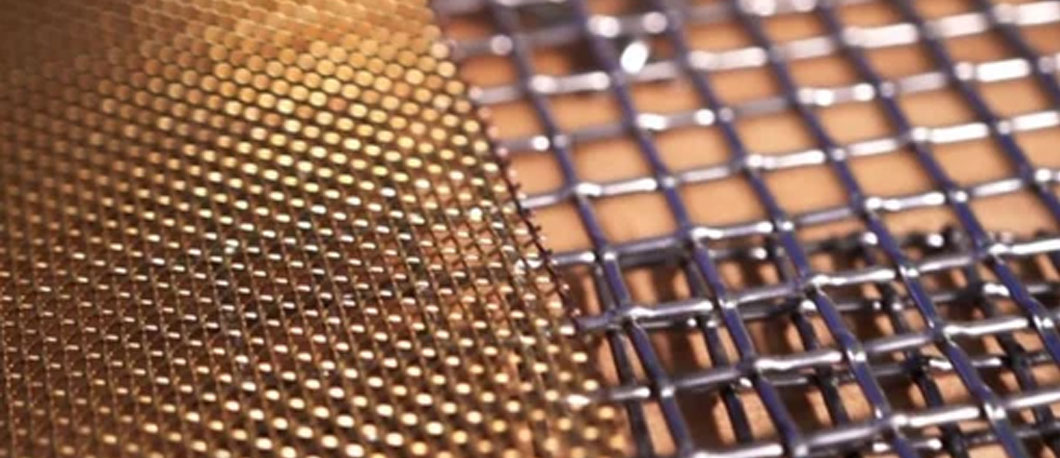

What is Nichrome A Wire Mesh?

Nichrome A wire mesh is a high-temperature–resistant woven or welded mesh made from an alloy of nickel (80%) and chromium (20%). Known for its stable electrical resistance, excellent heat tolerance, and anti-oxidation properties, it is widely used in heating elements, resistive coils, and thermal processing equipment.

Why It’s Ideal for Heating Element Design

Nichrome A is a globally preferred heating material due to its ability to generate and withstand heat over extended cycles. When fabricated as a mesh, it offers:

- Uniform resistance for consistent heat distribution

- High melting point (~1400°C) suitable for extreme heat environments

- Rapid heating and cool-down without structural degradation

- Long service life even under continuous current flow

This makes it a go-to solution for furnace linings, toaster grids, kilns, industrial heaters, and laboratory heating systems.

Trends, Challenges & Common Buyer Questions

🔼 Industry Trends:

- Rise in nichrome mesh heating panels for lab, ceramic, and infrared applications

- Adoption of nichrome screens in embedded heating mats for advanced manufacturing

- Growing demand in electric vehicle battery pre-heaters and aerospace ovens

❓ Common Questions:

- What’s the difference between Nichrome A and Kanthal or stainless steel mesh?

- Can Nichrome mesh be used directly as a heating element?

- How is mesh heating different from coiled wire heating?

- Is Nichrome A safe and reliable for high-frequency thermal cycling?

🔗 Explore Nichrome A Wire Mesh

How Nichrome A Mesh Performs in Heating Systems

At IG Wire Screen Co., we supply Nichrome A wire mesh specifically tailored for industrial and precision heating systems. It provides:

- Stable electrical resistance for predictable thermal output

- High-temperature oxidation resistance, even in open air

- Mechanical durability under heat expansion/contraction cycles

- Excellent weldability and formability into plates, tubes, or custom-shaped mesh

Compared to wire coils, Nichrome mesh distributes heat more evenly, making it suitable for panel-based heaters, heat shields, or large-surface thermal units.

Applications of Nichrome A Wire Mesh in Heating

| Application Area | Role of Nichrome Mesh |

|---|---|

| Electric Furnaces & Kilns | Primary heating surface inside the chamber |

| Infrared Heaters | Radiant mesh element with fast heat-up cycles |

| Toaster / Oven Grills | Direct contact mesh heaters for food processing |

| Laboratory Heating Panels | Mesh integrated into ceramic or mica insulators |

| Plastic and Textile Processing | Surface heaters and drying sections |

| EV Battery Heating & Aerospace | Light-weight mesh for pre-heating and insulation |

Nichrome mesh is also used in defrost systems, heating blankets, and tubular heating assemblies where flexibility and efficiency matter.

Technical Specs of Nichrome A Mesh

- Alloy Composition: ~80% Nickel, ~20% Chromium

- Melting Point: ~1400°C

- Electrical Resistivity: ~1.1–1.4 μΩ·m

- Temperature Limit: Up to 1150°C continuous use

- Wire Diameters: 0.2 mm to 1.2 mm

- Mesh Counts: 2 mesh to 60 mesh

- Available Forms: Rolls, cut panels, circular discs, spiral-welded elements

- Surface Finish: Oxide-resistant; customizable as per heat profile needs

Our nichrome mesh can be welded to lugs, framed, or layered into multi-mesh heating cartridges.

Case Study: Heating Mat Panels for Ceramic Industry

A ceramics manufacturer needed a low-profile, even-heating surface for their tile drying tunnel.

We supplied:

- 20 mesh Nichrome A mesh (0.5 mm wire)

- Cut and edge-welded into heater mats

- Mounted over ceramic insulation with temperature controllers

✅ Outcome: Achieved uniform surface heat (±5°C) across 8-meter beds with reduced energy draw.

Nichrome A vs Stainless Steel & Kanthal Mesh

| Feature | Nichrome A Wire Mesh | SS 304 / 316 Mesh | Kanthal Mesh |

|---|---|---|---|

| Max Operating Temp | ~1150°C | ~700–800°C | ~1300°C |

| Electrical Conductivity | Moderate | Low | Moderate |

| Corrosion Resistance | Excellent in air | Good, may oxidize above 600°C | Excellent, especially in air |

| Thermal Cycling | Excellent | Moderate | Excellent |

| Flexibility/Formability | High | Moderate | Rigid (at higher wire gauges) |

| Best Use Case | Surface heating, panels | Structural or general use | Tubular or coil heating units |

🔗 Compare with SS 304 Wire Mesh

🔗 Explore 316 SS Welded Mesh

Why IG Wire Screen for Nichrome A Mesh?

- ✅ High-resistance alloy mesh in stock

- ✅ Available in coils, rolls, or pre-cut heating shapes

- ✅ Ready for electrical connection (lugs, tabbed ends)

- ✅ Advisory support on heat calculations and mesh loading

- ✅ ISO-compliant material traceability and fast delivery

From OEMs to R&D labs, we power up heating innovation with mesh that performs.

Ready-to-Use Nichrome Mesh Supply & Export Support

At IG Wire Screen Co., we offer:

- 🔥 Nichrome A mesh in cut panels, rolls, or pre-fitted elements

- ⚙️ Welded mesh with terminals for easy current connection

- 📦 Industrial and R&D-ready export packaging

- 📄 Technical support with watt density calculation and material resistivity charts

- 🌍 Fast delivery to India, Gulf, Europe, and SE Asia

Whether you’re a heater OEM or thermal systems engineer, we deliver ready-to-install heat control mesh built for performance.

Buyer Tips for Selecting Nichrome A Mesh

✔️ Choose 10–30 mesh for radiant panels or embedded ceramic heating

✔️ Use finer mesh (40–60) for low-wattage, controlled heating zones

✔️ Confirm maximum temperature and electrical load before selection

✔️ Ask for tabs or connection-ready terminals if integrating into circuits

✔️ Use mesh format instead of coil when you need even, surface-based heating

→ Request a Quote or Sample Cut Panel

🔍 Voice Search Optimized FAQs

Q1. What is Nichrome A mesh used for?

It’s used as a heating element in furnaces, ovens, laboratory heaters, and radiant panels.

Q2. Can Nichrome mesh replace heating coils?

Yes. Mesh offers even heat distribution and better surface control compared to coiled wire.

Q3. What temperature can Nichrome A mesh withstand?

It can handle up to 1150°C continuously, with excellent oxidation resistance in air.

Q4. Is Nichrome A electrically conductive?

Yes. It has stable resistivity, making it ideal for resistance heating applications.

Q5. What mesh sizes are best for heating panels?

20–40 mesh is commonly used in embedded or surface heating panels. Custom sizes available.

Q6. Can it be used for heating food or lab equipment?

Yes. It’s commonly used in toasters, ovens, and cleanroom lab heaters.

Q7. Do you offer welding or tabbing on mesh?

Yes. We supply welded lugs, spot-welded tabs, and edge-prepped panels for electrical integration.

Q8. Where can I buy Nichrome A mesh in India or for export?

From IG Wire Screen Co. — your trusted supplier of heating-grade mesh worldwide.

📢 Call to Action – Heat Smarter, Last Longer

From R&D labs to industrial ovens, your heating system deserves mesh that’s efficient, durable, and safe.

Nichrome A mesh is the global standard for surface-based electrical heating—and we make it work for you.

🧾 Request Datasheet or Heating Chart

📥 Ask for Sample Panel or Roll Pricing

🔌 Connect with Our Heating Mesh Specialist

→ Contact IG Wire Screen Co. Today

🧠 Final Takeaway: Where Heat Meets Control

Nichrome A wire mesh gives you thermal reliability, resistance stability, and design flexibility—all in one material.

It’s not just about heating—it’s about controlling heat safely, evenly, and efficiently.