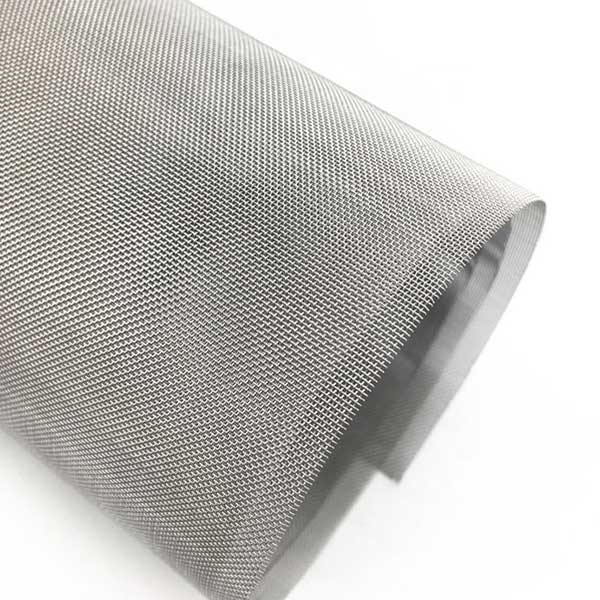

Nickel Wire Mesh

Table of Contents

Nickel Wire Mesh Supplier

Nickel wire mesh is a specialized type of wire cloth woven from nickel alloy wires. This alloy primarily consists of nickel, but it may also contain trace amounts of other elements like chromium, iron, and copper. Nickel mesh is known for its excellent corrosion resistance, even in harsh environments, making it suitable for applications where exposure to corrosive substances is a concern. Additionally, it exhibits high thermal conductivity, making it useful in applications involving heat transfer. This material finds a range of uses in industries such as chemical processing, aerospace, and electronics, where its unique combination of properties is highly valued.

It is employed in processes like filtration, sieving, and shielding, and it serves as an essential component in various industrial equipment and machinery. Due to its durability, resistance to corrosion, and thermal conductivity, nickel wire mesh is an indispensable material in industries that require reliable and long-lasting performance under demanding conditions. Indo German Wire Screen Co. stands as a prominent Nickel wire mesh supplier, manufacturer, and exporter based in India. We cater to various industries, providing them with top-notch solutions for their meshing requirements.

Advantages/ Features of Nickel Wire Mesh

Nickel wire mesh offers a range of advantages and features that make it a valuable material in various industrial applications. Here are some of its key advantages and features:

- Corrosion Resistance: Nickel wire mesh is highly resistant to corrosion, making it an excellent choice for environments where exposure to moisture or harsh chemicals is a concern. This resistance helps prolong the lifespan of the mesh.

- Stability and Alkali Resistance: It exhibits exceptional stability and is particularly resistant to alkalis. This makes it suitable for applications in industries where contact with strong alkaline substances is common.

- Acid, Alkaline, and Neutral Salt Resistance: Nickel wire mesh demonstrates superior resistance and stability in a wide range of pH environments, including acidic, alkaline, and neutral solutions. This versatility allows it to be used in diverse industrial settings.

- Resistance to Dry Gases at Room Temperature: It maintains its structural integrity even when exposed to dry gases at room temperature. This quality is valuable in applications where exposure to gases is a consideration.

- High Strength and Durability: Nickel wire mesh is known for its high tensile strength and durability. It can withstand mechanical stresses and pressures, ensuring it maintains its integrity in demanding conditions.

- Excellent Electrical Conductivity: Nickel is a good conductor of electricity, making this mesh suitable for applications where electrical conductivity is required.

- Temperature Stability: It retains its properties at a wide range of temperatures, which enhances its applicability in environments with varying thermal conditions.

- Non-Magnetic: Nickel is a non-magnetic material, which can be important in applications where magnetic interference is a concern.

- Clean and Aesthetic Appearance: Nickel wire mesh has a clean and aesthetically pleasing appearance, making it suitable for applications where visual appeal is important.

- Easy to Fabricate and Install: It can be easily cut, shaped, and installed, making it a versatile material for various applications.

- Chemical Compatibility: Nickel is compatible with a wide range of other materials, allowing it to be used in conjunction with different substances without risk of chemical reactions.

- Suitable for High-Temperature Applications: Nickel wire mesh retains its properties at elevated temperatures, making it a viable option for applications involving high heat.

Overall, the combination of corrosion resistance, chemical stability, and high strength makes nickel wire mesh a valuable material in industries such as chemical processing, petrochemical, aerospace, filtration, and more.

Applications/Usage of Nickel Wire Mesh

Nickel wire mesh finds a wide range of applications across various industries due to its unique properties. Some of the key applications include:

- Nickel Catalysts: Nickel wire mesh is utilized in the production of catalysts, especially in chemical processes where corrosion resistance and stability are crucial.

- Electrodes for Fuel Cells and Batteries: It is used in the manufacturing of electrodes for fuel cells and batteries, where its corrosion resistance and electrical conductivity are essential for efficient energy conversion.

- Filtration Media: Nickel wire mesh is commonly employed as a filtration medium for both liquids and gases. Its corrosion resistance and fine mesh structure make it suitable for applications where precise filtration is required.

- Corrosive Environments: It is chosen for applications in corrosive environments, where its high resistance to corrosion ensures longevity and effectiveness in filtering corrosive substances.

- Aerospace and Aviation: Due to its high strength and resistance to corrosion, nickel wire mesh is employed in aerospace and aviation applications, including filtration systems for aircraft engines.

- Petrochemical Industry: It finds use in the petrochemical industry for tasks such as filtering corrosive liquids and gases, and in processes involving the handling of petrochemicals.

- Medical and Pharmaceutical: It is utilized in the medical and pharmaceutical industries for tasks such as filtration in laboratories and specialized chemical processes where corrosion resistance is paramount.

- Electronics and Semiconductor Manufacturing: Due to its electrical conductivity and resistance to corrosion, nickel wire mesh is employed in the electronics industry for applications like electromagnetic interference (EMI) shielding.

- Battery Production: Nickel wire mesh is used in the production of batteries, including rechargeable nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH) batteries, where it serves as an integral component of the electrode structure.

- Environmental Protection: It is used in environmental protection applications, such as air and water filtration systems, where its corrosion resistance and fine mesh structure are crucial for effective filtration.

Overall, the versatility, corrosion resistance, and high stability of nickel wire mesh make it an indispensable material in a wide range of industries and applications, particularly in environments where corrosion or chemical resistance is a critical factor.

Order the products your company requires, Contact Indo German Wire Screen Co. at 91 - 9820291268 or submit an Enquiry Form for more information on any of our high quality products and get quotes within hours.

For more information, please Download Brochure

Nickel Wire Mesh Supplier Latest Price

| Nickel Wire Mesh Supplier Latest Price: | ____________ Rs/pc |

*Prices shown above are provisional prices and may change due to different market conditions. For latest prices please Contact Us at 91 – 9820291268 or send an enquiry through the Enquiry Form to get the final price within hours. Please request the updated price list and ready stock information along with your requirement. Indo German Wire Screen Co. maintains a stock of all standard items and can supply them at the best price.

Specifications of Nickel Wire Mesh Supplier

| Company | Indo German Wire Screen Co. |

| Category | Wire Mesh |

| Product name | Nickel Wire Mesh |

| Material | Nickel |

| Dimensions | ASTM, ASME, and API |

| Specifications | ASTM B160 / ASME SB160 |

| Wire Diameter | 0.05 mm-16 mm |

| Mesh Size | up to 250 mesh/inch |

| Length | Max 12000 mm |

| Diameter | 100 mm To 6000 mm |

| Packaging Details | Rolls / As per client’s requirement. |

Get Latest Price

Search for Tags: Nickel Wire Mesh manufacturers, nickel wire mesh price, nickel mesh price, stainless steel wire mesh manufacturers, wire mesh, chicken mesh, steel jali

About Indo German Wire Screen Co.

Indo German Wire Screen Co. is one of the leading manufacturer, supplier, and exporter and stockist of industrial Wire Mesh, Wire Cloth, Wire Screen, Wire Netting Knitted Wire Mesh, Welded Wire Mesh, Expanded Mesh, Woven Wire Mesh, Fine Wire Mesh, Galvanized Wire Mesh, Epoxy Coated Wire Mesh, Wire Mesh Filter, Demister Pad, Vibrating Screen Wire Mesh, Wire Mesh, Conveyer belt, Sifter Sieves, Perforated Sheets, and many more products in India manufactured. These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards.

We have become a major supplier of these products into an extensive range of markets and applications across India and the globe. Our clients select our range of products for their economical prices, dimensional preciseness, and high-durability. At Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers and moreover some of the factors that have consistently fuelled our growth in the national as well as international market are:

Why Indo German Wire Screen Co.

- More than 25 years of expertise in manufacturing and supplying wire mesh products.

- High-quality and superior-performance international quality products.

- Competitive pricing, on time delivery and customized solutions.

Industries We Serve

| Aeronautics Industry | Agriculture Sector | Dryers Industries | Fabrication Industry |

| Food Processing Industry | Building And Construction | Asbestos Industry | Pharmaceuticals Sector |

| Pulp And Paper Industry | Atomic Power Station | Fertilizer Sector | Pulverising Units |

| Automobile Industry | Coal Mines Industries | Granules manufacturing | Cement Industry |

| Glass Industry | Rubber Industries | Dehydration Plant | Steel Industry |

| Ceramic Tile Industry | Imitation Jewellery | Stone Crusher | Chemical Industry |

| Mining Sector | Irrigation Projects | Straw Board Industry |

Market Area of Indo German Wire Screen Co.

African Countries

South Africa , Nigeria, Kenya, Ghana, Ethiopia, Tanzania, Johannesburg, Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cabo Verde, Cameroon, Central African Republic (CAR), Chad, Comoros, Democratic Republic of the Congo, Côte d’Ivoire, Djibouti, Egypt, Equatorial Guinea, Eritrea, Gabon, Gambia, Guinea, Guinea-Bissau, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Nigeria, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Sudan, Sudan, Swaziland, Togo, Tunisia, Uganda, Zambia, Zimbabwe.

Gulf and other Countries

Oman, Qatar, Kuwait, Saudi Arabia, Dubai, Bahrain, Iran, United Arab Emirates, Australia, Sydney, Queensland, Melbourne, Perth, Adelaide, New Zealand, Auckland, Wellington, Hamilton.

Asian Countries

Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, Cyprus, Georgia, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, North Korea, Oman, Pakistan, Palestine, Philippines, Qatar, Russia, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Timor-Leste, Turkey, Turkmenistan, Uzbekistan, Vietnam, Yemen

South American Countries

Argentina, Ecuador, Suriname, Bolivia, Brazil, Guyana, Uruguay, Chile, Colombia, Paraguay, Peru, Venezuela

Note: Please note that the information on this document is for illustration purposes only as information may vary with individual products, their grade and applications, industries or uses and therefore cannot be guaranteed as accurate. © Copyright 2022 © Indo German Wire Screen Co. All Rights Reserved (Terms of Use). Recreation of any materials from the site is strictly prohibited without permission. Indo German Wire Screen Co. products are sold exclusively through Indo German Wire Screen Co. website. Use Terms | Privacy. Please contact us to discuss precise product specifications and requirements and obtain advice on which products are required to suit your exact application needs contact us at [email protected]