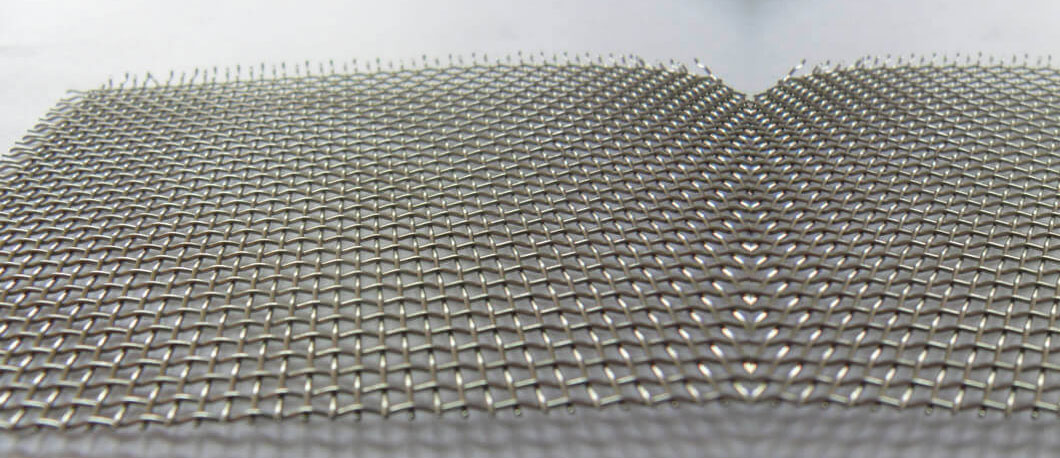

Tungsten wire mesh stands out as a remarkable solution for applications requiring extreme temperature resistance, exceptional strength, and superior durability. As one of the most heat-resistant metals, tungsten boasts a melting point of 3422°C, making it indispensable across industries like chemical, electronics, mechanical, and aerospace.

Whether it’s high-temperature furnaces, electronic devices, or specialized industrial uses, tungsten wire mesh proves its worth as a reliable, high-performance material. Explore our range of tungsten wire mesh products for versatile applications.

Key Properties of Tungsten Wire Mesh

- High Melting Point:

- With a melting point of 3422°C, tungsten offers unparalleled resistance to extreme heat.

- Thermal Resistance:

- Low thermal expansion and vapor pressure ensure tungsten remains stable in high-temperature environments.

- High Strength:

- Outstanding tensile strength maintains its structural integrity under stress.

- Electrical and Thermal Conductivity:

- Ideal for applications requiring efficient energy transfer.

- Radiation Absorption:

- High density enables excellent absorption of X-rays and radioactive radiation, making it useful in shielding applications.

Visit our wire mesh page to learn more about tungsten’s impressive characteristics.

Applications of Tungsten Wire Mesh in Industry

- High-Temperature Heating:

- Used in furnaces, vacuum metalizing, and heat treatment grids for its heat endurance and stability.

- Electronic Equipment:

- Essential for cathode ray tubes, thermocouples, and other high-frequency devices.

- Mechanical Equipment:

- Functions as electromagnetic shielding nets and components in vacuum furnaces.

- Chemical Industry:

- Utilized in hydrogen production, acid manufacturing, and other high-pressure chemical processes.

- Aerospace and Ammunition:

- Commonly used in rocket nozzles, kinetic energy penetrators, and armor-piercing ammunition.

- Batteries and Energy Storage:

- An integral part of high-capacity batteries due to its durability and conductivity.

For industry-specific solutions, check out the our products page for detailed offerings.

Why Tungsten Wire Mesh Excels in High-Temperature Applications

- Resistance to Oxidation and Creep:

- Performs reliably even when exposed to prolonged high temperatures and stress.

- Dimensional Stability:

- Maintains shape under thermal and mechanical loads, making it suitable for precision applications.

- Compatibility with Other Materials:

- Works seamlessly with ceramics, glasses, and other industrial components.

- Eco-Friendly Alternative:

- Non-toxic and recyclable, making it an environmentally conscious choice for demanding applications.

Explore eco-friendly and durable solutions on our contact page.

Technical Specifications of Tungsten Wire Mesh

| Property | Details |

|---|---|

| Purity | 99.9% Pure Tungsten |

| Melting Point | 3422°C |

| Mesh Size | 10–180 Mesh |

| Wire Diameter | 0.02 mm–0.25 mm |

| Roll Width | 0.1 m–1.5 m |

| Thermal Conductivity | High |

| Vapor Pressure | Low |

| Density | 19.25 g/cm³ |

For more details, visit the tungsten wire mesh product page.

Installation and Maintenance of Tungsten Wire Mesh

- Installation Tips:

- Ensure proper tension and alignment during installation to maximize performance.

- Use compatible fasteners for secure mounting in high-temperature environments.

- Maintenance Advice:

- Clean using controlled atmospheres or specialized solutions to avoid damage.

- Regular inspections help identify oxidation or structural degradation early.

For expert installation advice, visit our contact page to get in touch with our team.

FAQs on Tungsten Wire Mesh

- Why is tungsten wire mesh ideal for high-temperature applications?

Tungsten’s unmatched melting point, low vapor pressure, and thermal resistance make it perfect for extreme heat environments like furnaces and high-frequency devices. - Can tungsten wire mesh be customized?

Yes, it can be tailored to specific requirements, including mesh size, wire diameter, and roll dimensions. Explore customization options on our wire mesh page. - Is tungsten wire mesh reactive with air?

Under normal conditions, tungsten wire mesh is stable. However, it oxidizes at temperatures exceeding 400°C in oxygen-rich environments.

Get High-Quality Tungsten Wire Mesh Today

Looking for the most reliable tungsten wire mesh for your industrial applications? Visit our tungsten wire mesh product page or contact us to learn more.