Nickel wire mesh stands as a testament to unparalleled strength and durability, making it a superior choice for a wide range of applications. Renowned for its exceptional tensile strength, nickel wire mesh offers robust support and resilience, making it an ideal solution for projects requiring enduring structural integrity. As we explore the superiority of nickel wire mesh, we will uncover the specific attributes that contribute to its strength, shedding light on why it stands out as a prime material for various industrial, architectural, and filtration applications.

Unveiling the Strength: The Superiority of Nickel Wire Mesh Explained

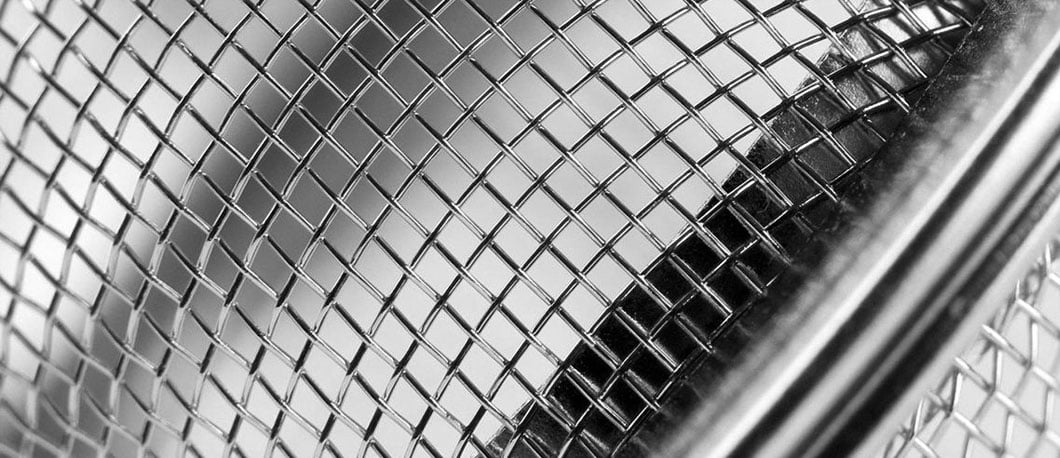

Nickel wire mesh is a type of woven wire mesh or cloth made from nickel wire strands. Nickel is a metallic element known for its corrosion resistance, high temperature stability, and excellent electrical conductivity. These properties make nickel wire mesh suitable for various applications across different industries. The mesh is created through a weaving process, where individual nickel wires are intertwined in a pattern to form a flexible and durable mesh structure. The weaving patterns can vary, affecting the mesh’s strength, openness, and other characteristics.

Nickel wire mesh finds applications in industries such as chemical processing, aerospace, electronics, and filtration. Its corrosion-resistant nature makes it suitable for use in environments with harsh chemicals or high temperatures. In filtration applications, nickel wire mesh is often chosen for its ability to withstand corrosive substances while providing precise filtering capabilities. Overall, nickel wire mesh is a versatile material valued for its strength, corrosion resistance, and electrical conductivity, making it a preferred choice in diverse industrial and commercial applications.

Versatility in Action: Where Nickel Wire Mesh Triumphs in Various Applications

Nickel wire mesh stands as a versatile and indispensable material across an array of applications, showcasing its prowess in diverse industries. In chemical processing, its corrosion resistance makes it a stalwart in handling corrosive substances, ensuring longevity and reliability in critical operations. The aerospace industry benefits from nickel wire mesh due to its lightweight nature and ability to withstand extreme temperatures, contributing to the structural integrity of components.

Electronics find a valuable ally in nickel wire mesh, given its excellent electrical conductivity. This makes it an ideal choice for applications where precision and reliability in signal transmission are paramount. Infiltration and filtration processes leverage nickel wire mesh for its ability to provide accurate and efficient separation, ensuring purity in various substances.

Architectural projects also witness the triumph of nickel wire mesh, where it seamlessly integrates functionality with aesthetics. From decorative elements to structural components, its versatility allows architects and designers to explore creative possibilities.

Elevate Your Projects: The Top Benefits of Opting for Nickel Wire Mesh

Choosing nickel wire mesh for your projects brings a multitude of benefits that elevate both performance and longevity. First and foremost, nickel’s exceptional corrosion resistance ensures durability in harsh environments, making it a reliable choice for applications exposed to corrosive elements. The inherent strength of nickel wire mesh adds structural integrity to your projects, providing robust support and longevity.

Moreover, nickel’s excellent electrical conductivity makes this mesh an optimal choice for projects in the electronics industry. It facilitates efficient signal transmission, ensuring reliability in various electrical applications. The versatility of nickel wire mesh allows it to seamlessly integrate into architectural designs, offering both functional and aesthetic advantages.

Infiltration and filtration processes also benefit from nickel wire mesh, as its precise weaving patterns enable effective separation without compromising flow rates. This feature is particularly valuable in industries where purity and precision are paramount.

Where Quality Meets Affordability: Your Guide to Buying High-Quality Nickel Wire Mesh

Navigating the market for high-quality nickel wire mesh involves a strategic balance between excellence and cost-effectiveness. We delve into the essential factors that define top-notch nickel wire mesh, ensuring that you not only meet stringent quality standards but also optimize affordability.

- Material Specifications: Understand the specific nickel alloy used in the wire mesh. Different alloys offer varying levels of corrosion resistance, strength, and conductivity.

- Weaving Patterns: Explore the available weaving patterns and their impact on the mesh’s strength, openness, and suitability for your intended application.

- Gauge Thickness: Gauge thickness plays a crucial role in determining the wire mesh’s durability and load-bearing capacity. Assess your project’s requirements to choose the right gauge.

- Industry Standards: Familiarize yourself with industry standards for nickel wire mesh. Reliable suppliers adhere to these standards, ensuring the mesh meets or exceeds performance expectations.

- Corrosion Resistance: Evaluate the mesh’s corrosion resistance properties, especially if it will be exposed to harsh chemicals or corrosive environments. Opt for nickel wire mesh that guarantees long-term durability.

- Budget Considerations: While quality is paramount, establish a budget that aligns with your financial constraints. Identify suppliers who offer a balance between quality and affordability.

This guide equips you with the knowledge needed to navigate the market for high-quality nickel wire mesh without compromising on affordability. Where quality meets cost-effectiveness, your purchasing decisions become an investment in the success and longevity of your projects.

Where to Buy: The Best Sources for High-Quality Nickel Wire Mesh

When seeking high-quality Nickel Wire Mesh, Indo German Wire Screen Co. emerges as a top-tier source renowned for the commitment to excellence. With a reputation built on reliability and product integrity, Indo German Wire Screen Co. stands out as a trusted supplier in the industry. We offer an extensive range of Nickel Wire Mesh products, catering to diverse applications with varying specifications. Our commitment to quality control ensures that each mesh meets stringent standards, providing customers with assurance regarding durability, corrosion resistance, and overall performance.