What is a Pressure Leaf Filter?

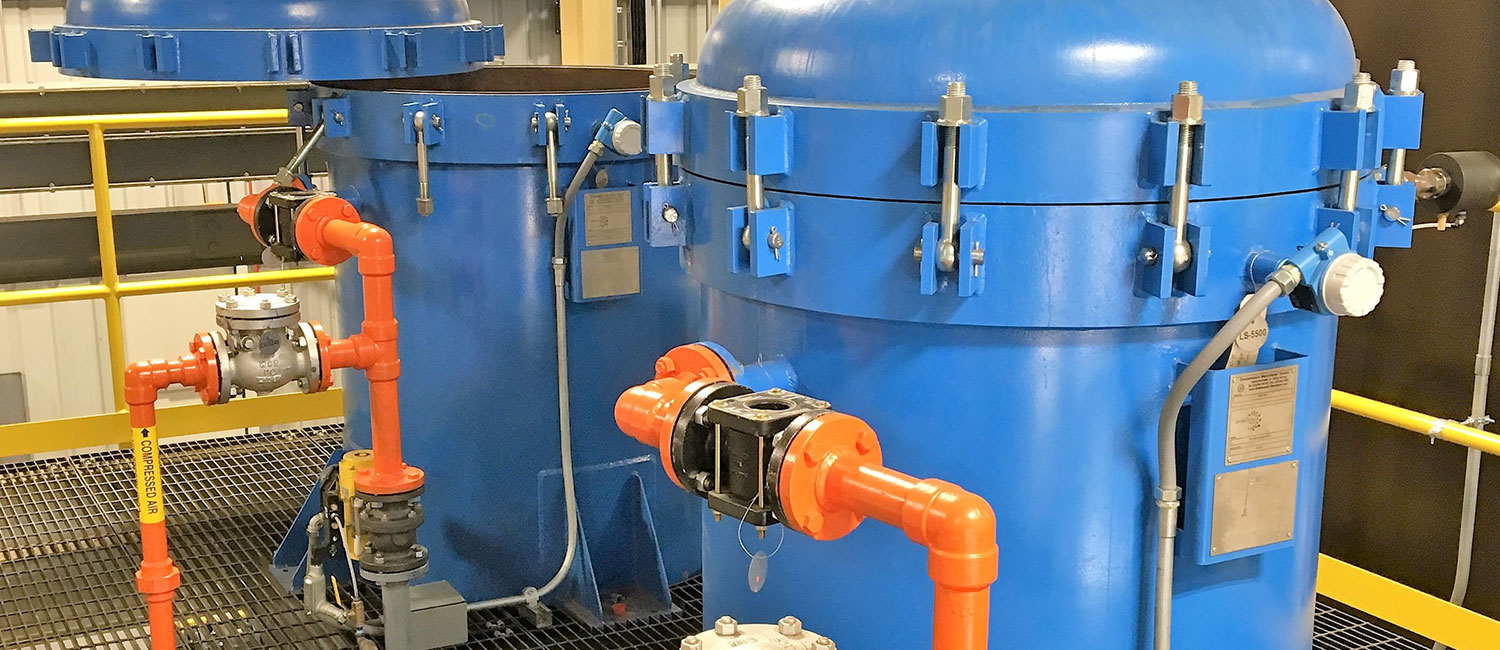

Pressure leaf filters are fluid/liquid filtration systems consisting of 10 to 60 leafs that are loaded inside a horizontal or vertical vessel. The leafs are drainage systems that support a textile or wire cloth cover. Since the filtration procedure is enclosed within a pressure resistant vessel, it can be a perfect solution for hazardous procedures.

What are the two types of Pressure Leaf Filters?

There are two kinds of leaf filter vessel configurations: vertical and horizontal pressure filters. Horizontal pressure filters are the most frequently operated due to the ease of operation and cleaning. There are also more variants of horizontal pressure filters due to the operation and installation techniques. Vertical pressure filters are frequently used for small-flow, granular media filtration. Horizontal vessels are typical for greater flows because the horizontal layout increases the filtration area potential. With vertical pressure filters, it is conceivable to have multiple vessels in one system, however with horizontal pressure filters, it is possible to have different cells in the same vessel.

How do Pressure Leaf Filters Operate?

A filter cycle initiates with the vessel sealing in the shaft and its filter leafs. Then, a precoat is presented. A precoat tank having filtrate and filter aid (diatomaceous earth, perlite, etc.) is agitated for about 10 minutes. Then, the mix fills the vessel, vents all the air and pressurizes. The precoat runs for 15 minutes at a fluid rate around 30- 60 gallons per square foot per hour.

After precoating, slurry is enforced through the vessel under pressure. Solid particles are stuck in the precoat, or filter media while clarified liquid passes through and into a filter leaf. The liquids pass from leaf to the shaft’s interior, then out of the filter into a holding tank.

Between batches, liquid cake or sludge is worn out from a valve. Dry cakes need a much larger opening, sometimes the whole vessel slides back for access to the leafs for discharge and cleaning.

Benefits of Pressure Leaf Filters

Pressure Leaf Filters have short regeneration time between filtration cycles, decreasing the operating costs as the filter can filtrate for extended periods without interruptions. The pressure filter leaves are easy to clean. Pressure Leaf Filters do not have any rotating parts that keeps the maintenance to minimum. The reinforced pressure filter leaves provide an extended lifecycle.

Conclusion

We at Indo German Wire Screen Co., manufactures and supplies Stainless Steel Wire Mesh for various industrial and commercial applications. Our Stainless Steel Wire Mesh is dimensionally precise which is used in Pressure Leaf Filter for lessening the down time of filtration significantly, owing to its mesh size. At Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.