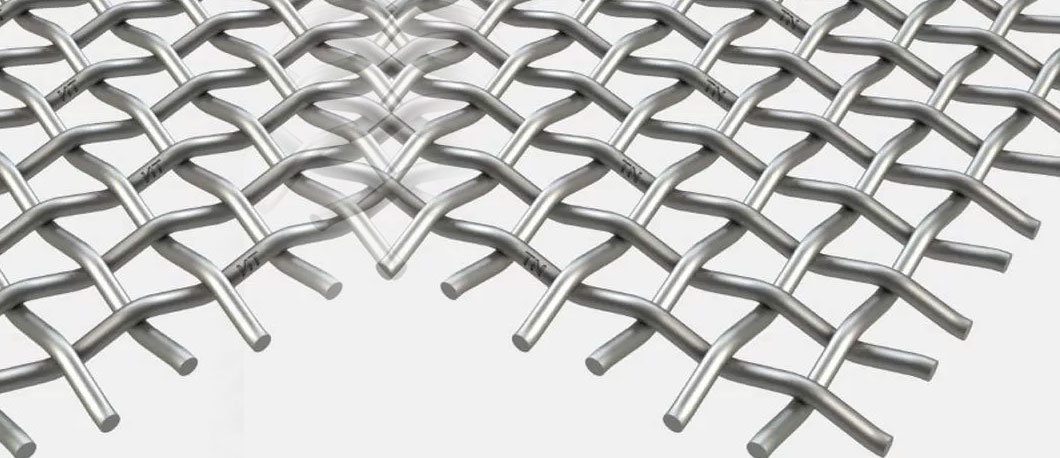

What is Aluminium 6061 Wire Mesh?

Aluminium 6061 wire mesh is a welded or woven metallic screen made from a heat-treatable aluminium alloy containing magnesium and silicon. Known for its high strength, corrosion resistance, and formability, it is widely used in transportation infrastructure, vehicle manufacturing, and aerospace components.

Why It’s Valuable in the Transportation Industry

Transportation systems require materials that are lightweight, durable, and weather-resistant. Aluminium 6061 mesh meets these needs due to its:

- High strength-to-weight ratio, reducing load on vehicles

- Resistance to corrosion and vibration, ideal for outdoor and mobile environments

- Weldability and machinability, supporting complex assemblies and modular use

- Compatibility with surface coatings for added UV or friction resistance

From roadway reinforcement to vehicle air intake filters, Aluminium 6061 mesh plays a vital role in mobility, safety, and efficiency.

Industry Trends, Challenges & Common Buyer Questions

🔼 Trends in Transport Manufacturing:

- Shift to lightweight metals to meet fuel efficiency and electric vehicle demands

- Use of mesh reinforcements in trailers, cargo beds, and ramps

- Adoption of mesh panels in public transit and rail projects for ventilation + security

❓ Buyer Questions:

- Is 6061 mesh strong enough for structural transportation parts?

- How does it compare to steel mesh for vehicle flooring or ramps?

- Can aluminium mesh be used in high-vibration transport environments?

- What coatings are available for anti-slip or UV protection?

🔗 Explore Aluminium Wire Mesh Options

🔗 Learn More About 6061 Aluminium Mesh

How Aluminium 6061 Mesh Enhances Transportation Applications

At IG Wire Screen Co., we supply Aluminium 6061 mesh that is engineered for performance in transportation systems—whether on road, rail, air, or sea.

Its key advantages in transport include:

- Lightweight but high-strength mesh to reduce fuel consumption

- Corrosion and abrasion resistance for long-term outdoor exposure

- Shock absorption under vibration, suitable for trailers and cargo enclosures

- Formability for grills, covers, vents, and flooring in custom shapes

It solves the challenge of balancing durability, safety, and efficiency—especially in weight-sensitive or mobility-focused projects.

Common Use Cases of 6061 Mesh in the Transportation Sector

| Application Segment | Role of Aluminium 6061 Mesh |

|---|---|

| Vehicle Body Panels & Grilles | Ventilation, filtration, and aesthetic enhancement |

| Cargo Trailers & Truck Beds | Anti-slip mesh flooring, ramp reinforcement |

| Railway Car Interiors | Screen guards, air diffusers, safety enclosures |

| Aerospace Equipment | Lightweight mesh components for airflow and EMI shielding |

| Bus & Metro Ventilation Grills | Heat- and corrosion-resistant air intake/exhaust |

| Marine & Port Transport Systems | Salt spray–resistant fencing and storage crates |

The durable yet lightweight nature of 6061 allows for versatility in both moving vehicles and fixed infrastructure.

Technical Specifications of Aluminium 6061 Mesh

- Alloy Composition: Al + 1% Mg + 0.6% Si (Heat-treatable)

- Tensile Strength: 260–310 MPa

- Mesh Sizes: 4 mesh to 100 mesh

- Wire Diameter Range: 0.25 mm to 1.2 mm

- Weave Types: Plain weave and welded mesh options available

- Surface Finishes: Mill finish, powder coated, anodized, anti-slip treatments

- Form Factors: Rolls, cut panels, shaped screens, flooring grates, stair treads

We offer customization of mesh to suit vehicle frame layouts, loading bay dimensions, and ventilation requirements.

Case Study: Lightweight Flooring for EV Cargo Vans

An EV fleet builder needed durable, non-corrosive mesh flooring that wouldn’t increase overall vehicle weight.

We delivered:

- Aluminium 6061 mesh in 5 mesh x 1 mm wire

- Powder-coated with anti-slip surface

- Cut to fit cargo flooring trays for 1,000+ vehicles

✅ Outcome: Saved 150 kg per vehicle in load weight, improved drainage and reduced maintenance frequency.

6061 Aluminium vs Stainless Steel Mesh in Transport

| Feature | Aluminium 6061 Mesh | Stainless Steel (304 / 316) Mesh |

|---|---|---|

| Weight | Light | Heavy |

| Strength-to-Weight Ratio | High | High, but with heavier mass |

| Corrosion Resistance | Very good (especially anodized) | Excellent (especially 316) |

| Machinability | Easy to cut, weld, bend | Tougher, may require special tools |

| Best For | Mobile, lightweight structures | Stationary or industrial structures |

| Cost | More affordable | More expensive |

🔗 Compare with 304 Stainless Steel Mesh

🔗 See 316 Stainless Steel Mesh for Marine Use

🔗 Explore Stainless Steel Welded Mesh Options

Why IG Wire Screen Co. for Aluminium 6061 Mesh?

- ✅ Transportation-grade mesh options in stock

- ✅ Anti-slip surface treatments available

- ✅ Custom CNC cutting + bending for mesh panel fitment

- ✅ Bulk supply to OEMs and transport contractors

- ✅ ISO-compliant documentation and material traceability

We understand what your fleet, vehicle, or transport infrastructure needs—and we deliver it light, fast, and strong.

Export Supply & Fabrication Services

At IG Wire Screen Co., we support the transportation sector with:

- 🚚 Bulk supply of 6061 aluminium mesh in sheets, rolls, and formed parts

- 🔧 Custom fabrication: stair treads, ramps, trailer flooring, grill panels

- 📦 Export-grade packaging for global shipping with minimal lead times

- 📄 Documentation support: test certificates, alloy traceability, MSDS, and HS codes

- 💡 End-to-end technical support for OEMs, contractors, and fleet integrators

From truck body manufacturers to aerospace OEMs, our mesh moves your business forward.

Buyer Tips for Using 6061 Mesh in Transport Projects

✔️ Use plain weave mesh (10–40 mesh) for ventilation grills or air intakes

✔️ Choose welded or 4–8 mesh for anti-slip flooring and load-bearing areas

✔️ Go with anodized surface for high-UV or coastal transport zones

✔️ Ensure the mesh is cut to vehicle frame dimensions for faster installation

✔️ Always demand tensile strength and load data if mesh will bear weight

→ Talk to Our Application Engineer Today

🔍 Voice Search Optimized FAQs

Q1. What is aluminium 6061 mesh used for in transportation?

It’s used in vehicle flooring, grills, cargo protection, ramps, filters, and ventilation systems.

Q2. Is 6061 mesh strong enough for trailer flooring?

Yes. It offers high tensile strength and load-bearing capacity, especially in welded mesh format.

Q3. Can aluminium mesh replace steel in transport projects?

Yes. It’s lighter and corrosion-resistant—ideal for reducing overall vehicle weight.

Q4. What coatings are available for aluminium 6061 mesh?

We offer mill finish, powder-coated, anodized, and anti-slip textured options.

Q5. Is it suitable for marine or coastal transport systems?

Yes. 6061 is corrosion-resistant, and anodized mesh performs well in salt spray environments.

Q6. Do you offer custom cutting or fabrication?

Yes. We provide precision-cut panels, bent mesh, and formed mesh flooring for transport structures.

Q7. How does 6061 compare to stainless steel in transportation use?

It’s lighter and easier to machine. SS offers more corrosion protection but adds weight and cost.

Q8. Where can I buy aluminium 6061 mesh for vehicles or transport projects?

At IG Wire Screen Co. — with ready stock, export supply, and engineering support.

📢 Call to Action – Strength That Moves

Whether you’re building vehicles, trailers, or transit systems, your mesh must be strong, light, and lasting.

🧾 Get a Quote for Custom 6061 Mesh Panels

📥 Download Mesh Load Chart / Spec Sheet

🔧 Schedule a Call for OEM Mesh Requirements

→ Contact Our Technical Sales Team

🧠 Final Takeaway: Lightweight Mesh, Heavy-Duty Performance

In transportation, every kilo matters. Aluminium 6061 wire mesh gives you the load-bearing capability of steel with the weight advantage of aluminium.

Built for motion. Backed by material science. Ready to move your project forward.