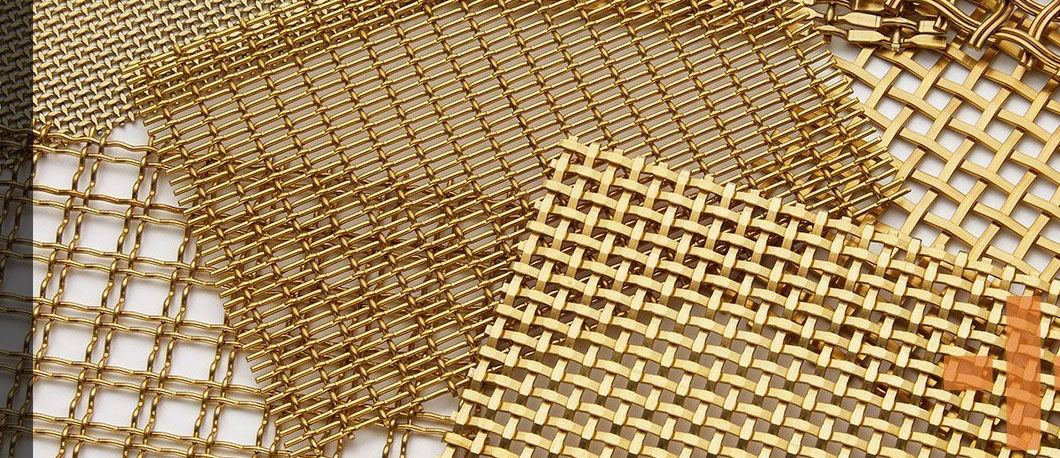

What is Brass Cartridge Wire Mesh?

Brass cartridge wire mesh is a woven metal screen made from a copper-zinc alloy, typically used in fluid filtration systems and strainer housings. Known for its anti-corrosive, non-sparking, and ductile properties, brass mesh is often shaped into cylindrical cartridges for use in oil, gas, water, fuel, and chemical filtration lines.

Why It’s Ideal for Industrial Strainer Applications

Brass wire mesh strikes the right balance between mechanical strength and chemical compatibility in many industrial processes. When formed into cartridge-style filters, it delivers:

- ✅ Excellent flow rates with fine filtration

- ✅ Malleability for deep-draw or custom cartridge housing

- ✅ Corrosion resistance in non-acidic fluids

- ✅ Non-sparking safety, ideal for oil & gas environments

This makes it a preferred material for removable strainers, pre-filters, and final filtration units across multiple industrial sectors.

Trends, Challenges & Common Buyer Questions

🔼 Current Trends:

- Use of brass cartridge mesh in hydraulic return lines and pump protection

- Demand for non-ferrous strainers in food, dairy, and brewery filtration

- Preference for brass over stainless steel in low-acid, high-flow environments

❓ Common Buyer Questions:

- Is brass mesh better than stainless steel for strainers?

- Can brass cartridge filters handle high pressure?

- What mesh sizes are best for water, oil, or coolant filtration?

- Can brass mesh be welded, brazed, or soldered for strainers?

🔗 Explore Brass Wire Mesh Options

How Brass Cartridge Mesh Enhances Filtration Systems

At IG Wire Screen Co., we supply brass wire mesh in cartridge-ready formats for use in industrial straining, filtration, and pump protection.

Brass mesh cartridges offer:

- 🔄 Reusable design for multiple cleaning cycles

- 🚿 High open area for uninterrupted fluid flow

- 🧱 Mechanical strength without compromising flexibility

- ⚡ Non-sparking safety for volatile or fuel-based environments

They’re compatible with filter housings, strainer baskets, cartridge sleeves, and inline flow filtration systems—making them a smart fit across multiple sectors.

Applications of Brass Mesh in Industrial Strainer Cartridges

| Industry / Fluid Type | Application of Brass Cartridge Mesh |

|---|---|

| Oil & Gas | Fuel strainers, diesel pre-filters, line screens |

| Water Treatment | Coarse sediment filters in pump intakes |

| Hydraulic Systems | Return line strainers, contamination guards |

| Food & Beverage | Strainers for syrups, juices, and brewing tanks |

| Textile & Paper Plants | Process water filters, pump safety screens |

| Pharma & Chemical | Non-reactive strainers for low-acid chemical flows |

Brass mesh is often formed into cylindrical cartridges, with open ends or capped formats, using spot welding, soldering, or mechanical clamping.

Technical Specs of Brass Cartridge Mesh

- Material Composition: Copper ~65%, Zinc ~35%

- Mesh Sizes Available: 4 mesh to 100 mesh

- Wire Diameters: 0.15 mm to 0.6 mm

- Form Options: Cut panels, rolled cylinders, pleated cartridges

- Surface Finish: Smooth (mill finish) or bright-polished

- Compatibility: Suitable for non-acidic, low-salinity liquids

- Fabrication: Can be soldered, riveted, or clamped into filters

We offer custom-fit cartridges, spot-welded mesh rolls, and brass sleeves for OEM filtration systems.

Case Example: Brass Mesh Cartridge for Hydraulic Return Line

A machinery OEM required a washable, corrosion-resistant mesh strainer for their hydraulic return assemblies. Stainless mesh clogged too fast due to fine sludge.

Solution:

- We supplied 60 mesh brass woven mesh, formed into 4” cartridges

- Soldered ends for pressure sealing

- Reusable up to 50 cleaning cycles

✅ Result: Improved flow, lower downtime, and 25% cost reduction in cartridge replacements.

Brass vs Stainless Steel for Cartridge Filters

| Property | Brass Mesh Cartridge | Stainless Steel Cartridge (304/316) |

|---|---|---|

| Corrosion Resistance | Good (non-acidic media only) | Excellent (including acids & salts) |

| Non-Sparking | Yes | No |

| Formability / Flexibility | High | Moderate |

| Cost | More economical | Higher (especially 316) |

| Weldability / Joining Options | Solderable, clampable | Weldable (TIG/MIG) |

| Best For | Water, oils, fuel, soft chemicals | Harsh chemicals, acids, marine environments |

🔗 Compare with SS 304 Wire Mesh

🔗 See 316 SS Mesh for Acidic Media

Why IG Wire Screen Co. for Brass Cartridge Mesh?

- ✅ In-house mesh forming and soldering for cartridge builds

- ✅ Custom sizing for OEM filter housings and process lines

- ✅ High-quality woven brass mesh in multiple mesh counts

- ✅ Tech support on mesh size selection and fluid compatibility

- ✅ Fast delivery with export packaging for bulk orders

From pump builders to filtration OEMs—we supply precision-fit brass cartridges that keep your system clean and efficient.

Customized Supply & Export-Ready Brass Mesh Cartridges

At IG Wire Screen Co., we specialize in:

- 🧩 Custom-fit brass mesh cartridges for inline strainers and filters

- 🔩 Soldered, rolled, or clamp-mounted mesh tubes for strainer housings

- 📄 Documentation support including mesh specs, pressure rating data & HS codes

- 📦 Export-ready packaging with moisture protection for global supply

- 🛠️ Fabrication options: edge-folded seams, spot welding, riveted mesh sleeves

Whether you’re building new filtration lines or replacing strainer components, our mesh is engineered for efficiency.

Buyer Tips for Choosing Brass Mesh for Strainers

✔️ Use 30–80 mesh for oil and hydraulic return lines

✔️ Choose fine mesh (80–100) for food, beverage, or fuel filtration

✔️ Opt for spot-welded or soldered cartridges for high-flow systems

✔️ Always confirm media compatibility — brass is ideal for non-acidic, low-saline fluids

✔️ For temporary strainers, request rolled mesh inserts with slip-fit dimensions

→ Talk to a Mesh Expert or Request a Sample

🔍 Voice Search Optimized FAQs

Q1. What is brass cartridge mesh used for?

It’s used in industrial strainers to filter water, oil, fuels, and low-acid chemicals.

Q2. Is brass mesh safe for fuel filtration?

Yes. Brass is non-sparking and ideal for fuel, diesel, and petrochemical strainers.

Q3. Can brass mesh be formed into filter cartridges?

Absolutely. It can be rolled, soldered, or clamped into cylindrical cartridges.

Q4. What mesh size is best for hydraulic oil strainers?

Typically 40 to 60 mesh depending on contamination level and flow rate.

Q5. Is brass better than stainless steel for strainer cartridges?

For non-acidic fluids, brass offers flexibility, non-sparking safety, and is more economical.

Q6. Can I reuse brass mesh filters after cleaning?

Yes. Brass mesh can be cleaned and reused multiple times if not chemically corroded.

Q7. Do you offer pre-fabricated cartridges or just mesh rolls?

We offer both: brass mesh rolls, cut sheets, and fully built cartridges for OEM use.

Q8. Where can I buy brass cartridge wire mesh in India or abroad?

At IG Wire Screen Co. — with ready stock and global delivery options.

📢 Call to Action – Clean Flow, Smart Filtration

Brass mesh offers the ideal balance of filtration, formability, and chemical safety.

Whether you’re straining hydraulic oil or screening debris in return lines, our brass mesh cartridges deliver long life and consistent performance.

🧾 Get a Quote for Brass Cartridge Mesh

📥 Download Mesh Size Chart / Compatibility Data

🔧 Ask for a Custom Cartridge Fitment Option

→ Contact IG Wire Screen Co. Today

🧠 Final Takeaway: Filter Better, Filter Brass

Brass cartridge mesh offers what industrial straining systems need: flow efficiency, non-sparking safety, and easy maintenance.

Choose a mesh that fits, flows, and lasts—backed by expert fabrication and reliable supply.