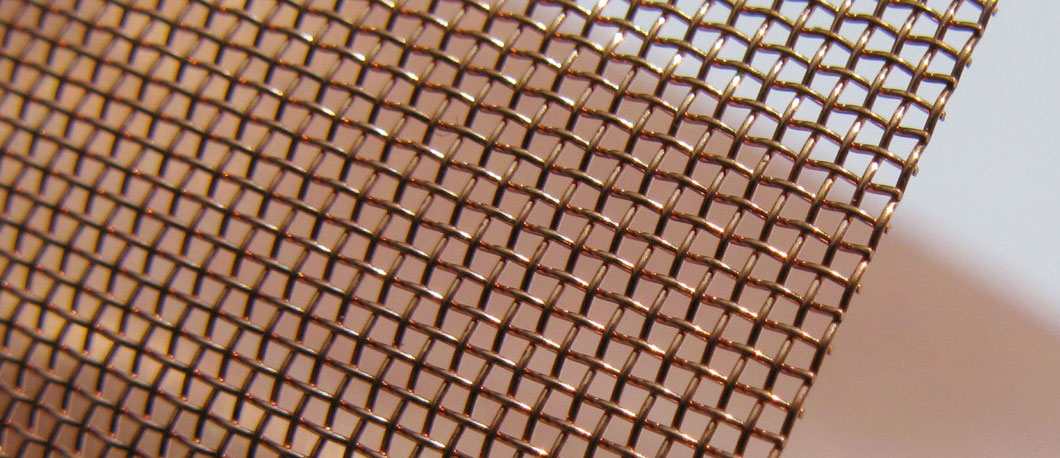

What is Phosphor Bronze Wire Mesh?

Phosphor bronze wire mesh is a precision-woven metallic screen made from a copper-tin-phosphorus alloy. Known for its strength, fine weave, and anti-corrosive properties, it is ideal for fine sieving, filtration, and separation in both industrial and laboratory settings.

Why It’s Important in Fine Sieving & Filtration

Phosphor bronze mesh is widely used in industries where particle size control, conductivity, and corrosion resistance are critical. It outperforms conventional meshes in delicate filtration tasks involving:

- Powders and fine granules

- Liquid-solid separation

- Chemical-resistant screening

- High-precision laboratory sieving

Its high tensile strength, non-sparking nature, and dimensional stability make it the mesh of choice for sensitive and high-accuracy applications.

Current Trends, Challenges & Common Questions

✅ Key Trends in Industrial Sieving:

- Shift from stainless steel to phosphor bronze in labs and pharma due to better flexibility

- Growth in ultrasonic sieving systems that demand stable, conductive mesh

- Increased demand from battery production, powder metallurgy, and pigment manufacturers

❓ Common Buyer Questions:

- What is the mesh count and wire diameter for micro sieving?

- How does phosphor bronze compare to SS304 or SS316 for chemical resistance?

- Can phosphor bronze mesh be used in automated vibratory sieves?

- Is it suitable for edible products like spice or flour sieving?

For applications where fine mesh with strength and anti-corrosion is critical, phosphor bronze is unmatched.

How Phosphor Bronze Mesh Solves Fine Sieving Needs

Phosphor bronze mesh offers the perfect balance of precision, conductivity, and corrosion resistance, making it highly suitable for industries where fine particle control matters. At IG Wire Screen Co., our phosphor bronze mesh is designed to solve key challenges like:

- Fine particle separation without clogging

- Electroconductive sieving in electronic and lab settings

- Anti-corrosive screening for wet or reactive substances

- Stable tension under vibration or mechanical stress

Whether you’re sieving pharmaceutical powders or filtering synthetic resins, our mesh delivers high accuracy and repeatable results.

Industry Applications: Where It Performs Best

| Industry / Application Area | Purpose of Phosphor Bronze Mesh |

|---|---|

| Pharmaceutical & Food | Ultra-fine powder screening, spice/flour sieving |

| Chemicals & Pigments | Non-reactive filtering of powders/slurries |

| Battery Manufacturing | Sieving metal powders for electrodes |

| Metallurgy & Foundries | Powder metallurgy and shot classification |

| Electronics & R&D Labs | Conductive mesh for EMI shielding and sieving |

| Aerospace & Defense | Precision filtration of combustibles, alloys |

Because phosphor bronze is non-sparking and chemically stable, it’s trusted in sensitive or explosive environments.

Technical Specifications & Fabrication

Our phosphor bronze wire mesh is manufactured with:

- Material Composition: Cu 94%, Sn 4.5%, P 0.5%

- Mesh Counts Available: 4 to 250 mesh

- Wire Diameter Range: 0.03 mm to 1.2 mm

- Roll Widths: Standard 1 m & 1.2 m (custom available)

- Weave Types: Plain weave, twill weave

- Finish: Natural polished finish or chemical-resistant coating

- Form: Available in rolls, cut sheets, or custom sizes

Custom fabrication is available for rotary sieves, test screens, and vibratory separators.

Case Example: Pharma-Grade Sieving Success

A pharmaceutical manufacturer required high-precision sieving for bulk paracetamol powder.

They switched from stainless steel mesh to our 200 mesh phosphor bronze screen, resulting in:

- 20% faster throughput with no powder loss

- Zero static build-up on fine particles

- Extended mesh life under high-frequency vibration

→ The result: Cleaner sieving, reduced contamination risk, and consistent batch quality.

Phosphor Bronze vs Stainless Steel: What’s Best for Sieving?

| Feature | Phosphor Bronze Mesh | Stainless Steel Mesh (304 / 316) |

|---|---|---|

| Particle Size Accuracy | Excellent for ultra-fine screening | Very good (slightly stiffer) |

| Flexibility | More pliable for delicate sieving | More rigid |

| Conductivity | High (useful for lab/electronics) | Low |

| Corrosion Resistance | Good (chemical applications) | Excellent (especially 316 grade) |

| Cost | Slightly premium | Cost-effective |

| Non-sparking | Yes (ideal for explosive environments) | No |

| Best Use Case | Precision sieving, lab filtration | General filtering, harsh environments |

🔗 Explore 304 Stainless Steel Mesh

🔗 Explore 316 SS Welded Mesh

🔗 Stainless Steel Welded Wire Mesh

Why Choose IG Wire Screen Co. for Phosphor Bronze Mesh?

- ✅ Trusted by 100+ global industries for fine filtration

- ✅ High mesh counts ready in stock (up to 250 mesh)

- ✅ Custom fabrication for sieves, test screens & automated separators

- ✅ Full support: datasheets, particle size charts, and export packaging

- ✅ Prompt delivery in India & overseas with industrial-grade QC checks

We don’t just supply mesh. We engineer solutions for your sieving challenges.

Export & Delivery Support

IG Wire Screen Co. offers pan-India and global delivery for phosphor bronze wire mesh. Our supply capabilities include:

- Export-grade packaging: moisture-resistant, vibration-safe bundling

- Bulk rolls & cut panels for OEMs, labs, and filter system integrators

- Documentation support: test certificates, mesh count validation, and HS code labeling

- Reliable logistics network for fast turnaround in Asia, Africa, and Europe

From trial orders to full container shipments—we deliver precision, fast.

Buyer Tips for Choosing Phosphor Bronze Mesh

✔️ Go with 100–250 mesh for fine powders and pharma-grade separation

✔️ Ask for twill weave if your application requires high mechanical stability

✔️ Use plain weave for general-purpose lab sieving

✔️ Confirm chemical compatibility based on the fluid/powder being handled

✔️ Opt for sheet cut format for ultrasonic sieves or hand screen frames

📞 Not sure? → Get Expert Help Here

🔍 Voice Search Optimized FAQs

Q1. What is phosphor bronze wire mesh used for?

It’s used for fine sieving, filtration, EMI shielding, and separation of powders in pharma, labs, and electronics.

Q2. Can phosphor bronze mesh handle corrosive environments?

Yes, it has good corrosion resistance to many chemicals, but for harsh acids, SS316 is recommended.

Q3. What is the finest mesh count available?

We offer up to 250 mesh phosphor bronze screens for ultra-fine sieving.

Q4. Is phosphor bronze safe for food and pharma use?

Yes, it’s non-toxic, non-reactive, and widely used in spice, flour, and bulk pharma powder sieving.

Q5. What sizes are available for phosphor bronze mesh?

Standard roll widths: 1 m & 1.2 m; custom cut sheets and round sieving frames available.

Q6. How does phosphor bronze compare to stainless steel mesh?

Bronze is more flexible and conductive; SS offers higher corrosion resistance.

Q7. Can phosphor bronze be used in vibratory or ultrasonic sieves?

Yes. It’s compatible with most mechanical and ultrasonic sieving machines.

Q8. Where can I buy phosphor bronze mesh in India or export it?

At IG Wire Screen Co., we supply both domestic and international markets with full documentation and fast delivery.

📢 Call to Action – Let’s Upgrade Your Sieving Precision

Your application deserves mesh that performs with clarity, conductivity, and control.

📩 Request a Quote for phosphor bronze mesh

📥 Download Particle Size Chart / Mesh Specs

🧪 Ask for a Sample Roll for Sieving Tests

→ Contact Our Team — Fast Response | Custom Cuts | Global Support

🧠 Final Takeaway: When Sieving Gets Serious, Go Bronze

In the world of fine sieving, every micron counts.

Phosphor bronze mesh gives you unmatched accuracy, reliability, and lifespan—especially when your product quality depends on every particle being in place.

Choose the mesh trusted by labs, manufacturers, and innovators worldwide.