In today’s fast-paced world, where industries are progressing promptly, it’s critical to make well-informed decisions when it comes to materials and products. One such vital consideration is the use of stainless steel wire mesh. This flexible and robust material has found its way into various applications across industries, providing unparalleled advantages and serving as a testament to the phrase “Invest in Quality.” Let’s dive into the world of stainless steel wire mesh and uncover its remarkable properties in various sectors.

Introduction to Stainless Steel Wire Mesh

Stainless steel wire mesh stands as a testament to the seamless blend of functionality and durability in the realm of industrial materials. Crafted from stainless steel wires that exhibit remarkable resistance to corrosion and wear, this unique fabric has garnered widespread recognition across various industries.

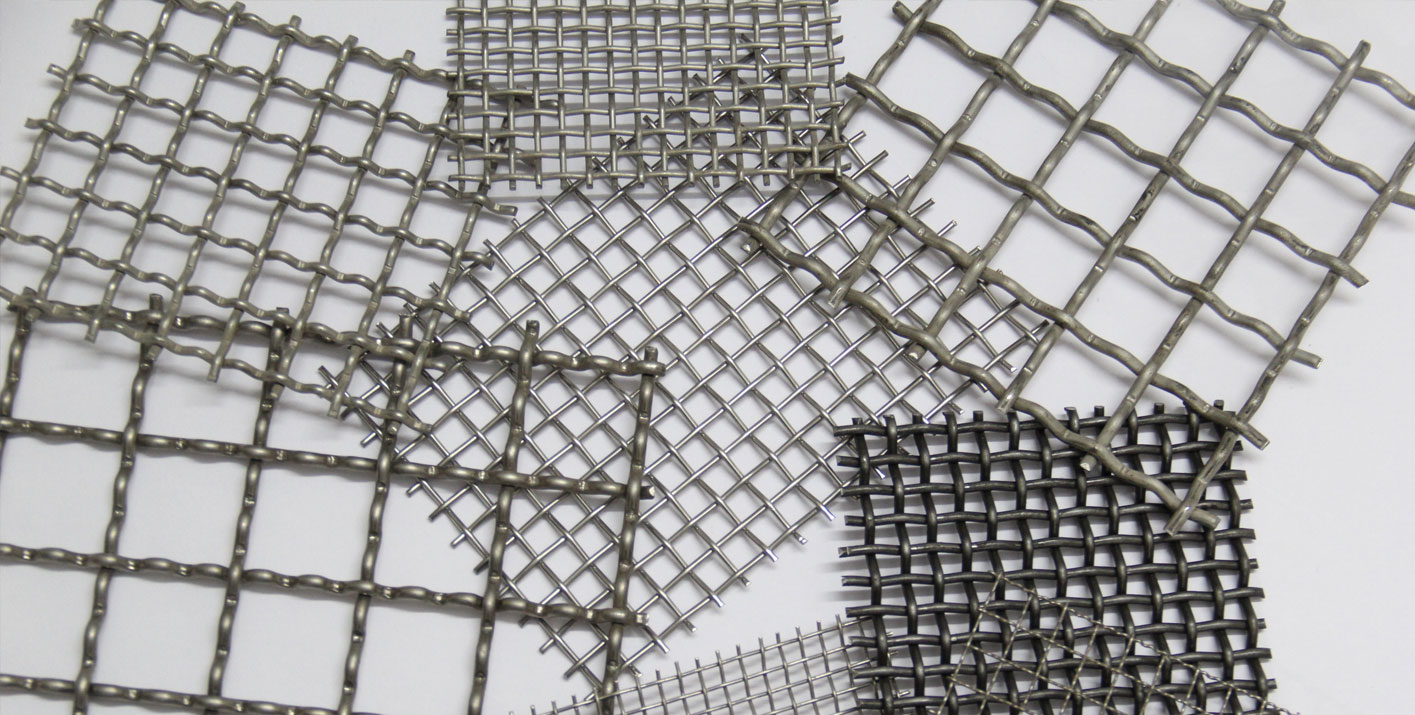

One of the most striking attributes of wire mesh is its exceptional strength, which stems from the inherent properties of stainless steel. This rigid wire mesh boasts remarkable tensile strength and toughness, allowing it to withstand considerable mechanical stress without succumbing to deformation. The manufacturing process of stainless steel wire mesh involves an intricate weaving technique. Skilled artisans interlace stainless steel wires in a precise pattern, resulting in a wide array of stainless steel wire mesh sizes. Each mesh size serves a distinct purpose, tailored to the specific demands of various applications. From coarser meshes that offer robust filtration and separation, to finer meshes suited for intricate sieving and particle retention, the versatility of stainless steel wire mesh knows no bounds.

Stainless steel wire mesh is a remarkable woven fabric that embodies durability, strength, and adaptability. Its intricate weaving process results in a spectrum of mesh sizes, each tailored to fulfil specific roles. With its corrosion resistance, longevity, and versatility, stainless steel wire mesh continues to be an indispensable asset across an array of industries, contributing to innovation and progress.

Unlocking the Value: Why Stainless Steel Wire Mesh Is Worth the Investment

In the world of industrial materials, few options offer the blend of durability, versatility, and reliability that stainless steel wire mesh does. If you’re seeking an investment that promises long-term value across a spectrum of applications, look no further than stainless steel wire mesh.

- Exceptional Strength and Durability: The hallmark of stainless steel wire mesh is its exceptional strength and durability. Unlike other materials that may falter under stress or corrosion, stainless steel wire mesh maintains its structural integrity even in demanding environments. This inherent strength makes it a preferred choice for applications that require a material capable of withstanding mechanical pressure and wear over time.

- Corrosion Resistance: A Game-Changer: One of the most compelling reasons stainless steel wire mesh stands out is its remarkable resistance to corrosion. This property is a result of the alloying elements within stainless steel, particularly chromium and nickel. These elements form a protective layer on the surface of the wire mesh, shielding it from the damaging effects of moisture, chemicals, and harsh weather conditions.

- Versatility Unleashed: Stainless steel wire mesh’s versatility is another aspect that makes it a worthy investment. Through an intricate weaving process, this material is available in various mesh sizes, each tailored to serve a specific purpose. From coarse meshes that excel in filtration and separation to finer meshes that allow precision sieving and particle retention, the adaptability of stainless steel wire mesh is truly unmatched.

- Longevity Beyond Compare: When you invest in stainless steel wire mesh, you’re investing in longevity. Its robust construction and corrosion-resistant nature mean that your projects will remain functional and reliable for years to come. Whether it’s for architectural accents, industrial sieving, or landscaping purposes, the enduring nature of stainless steel wire mesh ensures that your investment retains its value over time.

Comparing Options: Why Stainless Steel Wire Mesh Stands Out for Buyers

When buyers are in search of top-tier materials, stainless steel wire mesh emerges as a standout choice. Let’s explore why it outshines the competition.

- Unmatched Strength and Durability: Stainless steel wire mesh takes the lead in strength and durability. Unlike other materials that falter under pressure, stainless steel wire mesh thrives, making it an ideal pick for both heavy-duty industrial applications and intricate architectural projects.

- Defying Corrosion with Ease: The secret behind stainless steel wire mesh’s resilience lies in its composition. Enriched with chromium and nickel, it resists corrosion effortlessly. Whether it’s exposed to moisture, chemicals, or tough weather conditions, it stands its ground.

- Adaptability Across Industries: Stainless steel wire mesh offers versatility like no other. With various mesh sizes tailored for specific functions, it meets the needs of industries ranging from mining to agriculture and food processing. From robust filtration to precision sieving, it adapts seamlessly.

- Long-Term Value and Savings: Investing in stainless steel wire mesh is a smart move for long-term value. Its enduring strength translates to fewer replacements and minimal maintenance costs over time. This translates into significant savings and a solid return on investment.

Precision Filtration: How Stainless Steel Wire Mesh Elevates Buyer Processes

When it comes to precision filtration, stainless steel wire mesh takes buyer processes to new heights. Let’s delve into how this remarkable material enhances filtration solutions.

- A Foundation of Precision: Stainless steel wire mesh sets the stage for precision filtration. Its precisely woven structure ensures that even the tiniest particles are effectively captured, delivering superior filtration performance.

- Unwavering Strength: Buyers can rely on the unwavering strength of stainless steel wire mesh. Its robust composition enables it to withstand the pressure differentials that often come with filtration processes, ensuring longevity and efficiency.

- Corrosion Resistance for Reliability: Infiltration of moisture and chemicals can compromise filtration efficiency. Stainless steel wire mesh’s corrosion-resistant properties counter this threat, maintaining its performance over time and ensuring consistent results.

- Tailored to Excellence: With various mesh sizes available, stainless steel wire mesh can be tailored to fit specific filtration requirements. This adaptability allows buyers to choose the exact mesh size needed for optimal filtration efficiency.

- Investment in Efficiency: Opting for stainless steel wire mesh is an investment in filtration efficiency. Its durability and corrosion resistance translate to reduced downtime, lower maintenance costs, and a filtration process that remains reliable over the long term.

Fields of Application: Where Buyers Can Leverage Stainless Steel Wire Mesh

Buyers exploring the possibilities of stainless steel wire mesh will find its versatility applicable across various fields. Let’s uncover the diverse range of applications where this material can be effectively leveraged.

- Industrial Filtration and Separation: In industries like mining, oil and gas, and chemical processing, stainless steel wire mesh shines as a reliable solution for filtration and separation. Its sturdy construction and corrosion resistance make it ideal for separating solids from liquids and controlling particle size distribution.

- Food Processing and Beverage Industry: Stainless steel wire mesh plays a pivotal role in the food and beverage industry. It’s employed for sieving, sorting, and filtering processes, ensuring product quality by removing impurities and achieving consistent particle sizes.

- Architectural and Interior Design: Architects and designers use stainless steel wire mesh for aesthetic and functional purposes. It finds its way into building facades, decorative elements, and interior design components, adding a modern and sophisticated touch to spaces.

- Agriculture and Aquaculture: In agricultural settings, stainless steel wire mesh is used for fencing, animal enclosures, and plant protection. It also finds applications in aquaculture, serving as an effective stainless steel filter screen for fish farming and ensuring water flow while preventing predators.

- Medical and Pharmaceutical: The medical and pharmaceutical industries benefit from stainless steel wire mesh’s precision. It’s used for medical instruments, filtration of pharmaceutical products, and as components in implants and devices.

- Automotive and Aerospace: Stainless steel wire mesh is found in automotive and aerospace applications, providing reinforcement in composite materials, acting as a spark arrestor in exhaust systems, and contributing to safety features like airbag deployment.

- Environmental Protection: In environmental applications, stainless steel wire mesh is used in air and water filtration systems. Its durability and resistance to corrosion ensure effective filtration and separation of pollutants and particulates.

- Vibrant Creative Arts: Artists and craftsmen incorporate stainless steel wire mesh into sculptures, installations, and artworks. Its malleability and ability to hold various finishes make it a versatile medium for creative expression.

Adding Value to Agriculture: Stainless Steel Wire Mesh for Discerning Buyers

For buyers in the agricultural sector, the inclusion of stainless steel wire mesh brings unparalleled value. Let’s delve into how this versatile material enhances agricultural practices.

- Enhanced Fencing and Enclosures: Stainless steel wire mesh reinforces security and containment on agricultural properties. It’s an excellent choice for fencing, ensuring the safety of livestock and preventing unwanted intrusions while allowing for proper airflow.

- Protection from Pests and Predators: In crop cultivation, stainless steel wire mesh acts as a reliable shield against pests and predators. It creates barriers that prevent insects and animals from accessing plants, reducing the need for harmful chemicals and ensuring healthy yields.

- Aquaculture Advantage: In aquaculture, stainless steel wire mesh plays a vital role. It’s utilized in fish farming setups to create separation barriers and screens, facilitating controlled water flow and protecting fish stocks from external threats.

- Erosion Control: On slopes and areas susceptible to erosion, stainless steel wire mesh stabilizes the soil. Its mesh structure prevents soil erosion while allowing vegetation to establish, contributing to sustainable land management.

- Efficient Crop Support: Stainless steel wire mesh provides robust support for climbing crops like beans, peas, and cucumbers. Its strength ensures that plants receive the necessary elevation and support, leading to healthier growth and better yields.

- Greenhouse Excellence: In greenhouse environments, stainless steel wire mesh finds application as trellises, partitions, and protective screens. It creates well-organized growing spaces and aids in controlling the movement of air, light, and water.

- Water Management: Stainless steel wire mesh filters and screens irrigation systems, preventing debris and sediment from clogging pipes and nozzles. This ensures efficient water distribution, optimizing water usage and promoting sustainable practices.

- Longevity and Investment: By incorporating stainless steel wire mesh, agricultural buyers invest in longevity. Its resistance to corrosion and wear guarantees lasting performance, translating to reduced replacement costs and sustained productivity.

Making the Right Choice: Key Factors to Consider When Buying Stainless Steel Wire Mesh

When purchasing stainless steel wire mesh, several essential factors should guide your decision-making. Let’s explore the crucial considerations that ensure you make the right choice for your specific needs.

- Mesh Size and Application: Determine the mesh size that aligns with your intended application. Coarser mesh is ideal for heavy-duty tasks like industrial filtration, while finer mesh suits precision sieving and intricate applications like architectural design.

- Material Grade: Different grades of stainless steel offer varying levels of corrosion resistance and durability. Choose a grade that matches the environmental conditions your wire mesh will face. Common options include 304, 316, and 316L stainless steel.

- Corrosion Resistance: Assess the level of corrosion resistance required for your project. If your application involves exposure to moisture, chemicals, or harsh elements, prioritize stainless steel wire mesh with higher corrosion-resistant properties.

- Strength and Load-Bearing Capacity: Consider the mechanical stress your wire mesh will encounter. For heavy loads or structural applications, opt for wire mesh with higher tensile strength and load-bearing capacity to ensure lasting performance.

- Weaving Technique: Different weaving techniques, such as plain weave, twill weave, or Dutch weave, offer varying levels of strength and filtration efficiency. Choose the technique that aligns with your project’s functional requirements.

- Durability and Longevity: Invest in stainless steel wire mesh that guarantees durability and longevity. This ensures minimized maintenance costs and a prolonged lifespan, making it a cost-effective choice in the long run.

- Budget Considerations: Balance your requirements with your budget. While higher-grade stainless steel and specialized weaves might offer superior properties, they can also come at a higher cost. Choose a mesh that meets your needs without stretching your budget.

- Aesthetic Appeal: If your application involves architectural or decorative purposes, consider the visual aspect of the wire mesh. Stainless steel wire mesh offers a modern and sleek appearance that can enhance the aesthetic of your project.

- Supplier Reputation: Purchase from reputable suppliers known for delivering high-quality stainless steel wire mesh. Look for reviews, certifications, and industry recognition to ensure you’re investing in a reliable product.

- Customization Options: If your project demands unique specifications, inquire about customization options. Some suppliers offer tailored solutions that perfectly match your requirements.