What is Titanium Wire Mesh?

Titanium wire mesh is a lightweight, high-strength woven screen made from titanium alloys (typically Grade 2 or Grade 5), known for their exceptional corrosion resistance, even in aggressive chemical environments. It is widely used in chemical processing, filtration, separation, and containment systems where other metals fail.

Why It’s Ideal for Chemical Processing Applications

Chemical plants handle a variety of harsh substances—acids, alkalis, solvents, brines, and chlorides. Titanium mesh stands out due to its:

- Corrosion immunity in both oxidizing and reducing agents

- Non-reactive nature, preventing contamination or product degradation

- High mechanical strength at elevated temperatures

- Long service life with minimal maintenance or replacement cycles

From filter baskets to reaction vessels, titanium mesh ensures system safety, uptime, and chemical compatibility.

Key Trends, Challenges & Common Buyer Questions

🔼 Industry Trends:

- Increasing use of titanium-based equipment in green chemistry and cleanroom processing

- Shift from stainless steel to titanium in chlorine, bromine, and nitric acid environments

- Growth of titanium mesh use in energy storage, water treatment, and electrolysis plants

❓ Common Buyer Questions:

- How does titanium mesh compare with stainless steel or nickel alloys?

- Can it handle high-chloride and acidic conditions?

- Is titanium mesh suitable for high-pressure filter housings?

- What mesh sizes are available for liquid-solid separation?

How Titanium Mesh Solves Key Chemical Processing Challenges

At IG Wire Screen Co., we supply Grade 2 and Grade 5 titanium wire mesh that’s engineered to withstand the most aggressive chemical processing conditions.

Titanium mesh is ideal for applications involving:

- Chlorides, halides, nitric acid, seawater, and bleach solutions

- High-temperature processes and pressurized systems

- Electrochemical or catalytic reactions

- Contamination-sensitive environments (pharma, food-grade solvents)

When corrosion, contamination, or weight is a concern, titanium is the next-level material that performs beyond stainless, nickel, or even Hastelloy.

Applications of Titanium Wire Mesh in Chemical Plants

| Application Area | Function of Titanium Mesh |

|---|---|

| Filter Housings & Cartridge Screens | Non-reactive filtration of aggressive fluids |

| Acid & Alkali Reactors | Internal mesh lining for chemical stability |

| Cathode/Anode Electrolysis Meshes | Conductive + corrosion-proof in brine/electrolytes |

| Evaporator & Heat Exchanger Baffles | Salt-resistant screening for heat recovery units |

| Distillation Trays & Tower Packing | Support mesh for high-purity separation |

| Wastewater & Effluent Lines | Durable mesh strainers and debris guards |

Titanium ensures long-lasting, zero-leach filtration and separation under extreme chemical stress.

Technical Specs of Titanium Mesh

- Material Grades: Titanium Grade 2 (commercially pure) & Grade 5 (Ti-6Al-4V alloy)

- Corrosion Resistance: Excellent in chloride, fluoride, acidic and alkaline environments

- Mesh Sizes: 4 mesh to 150 mesh available

- Wire Diameters: 0.1 mm to 1 mm

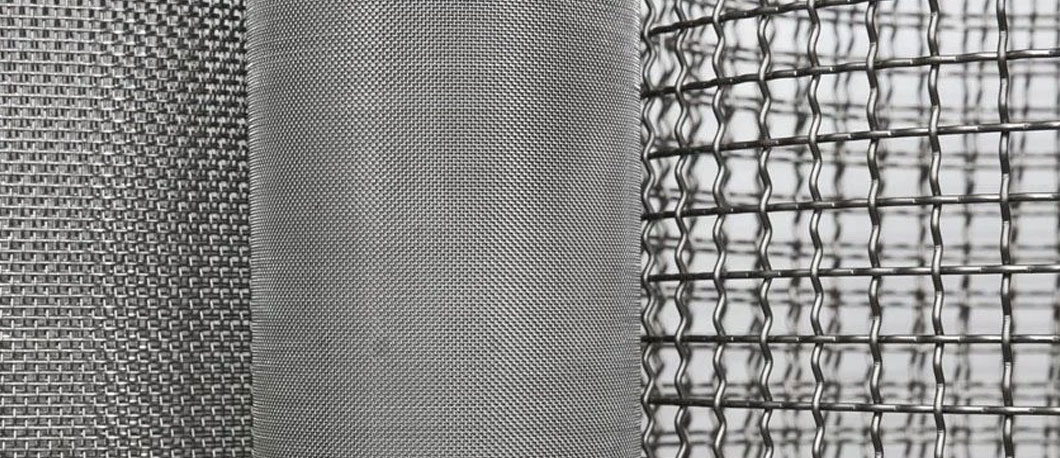

- Weave Types: Plain weave, twill weave, Dutch weave

- Form Options: Rolls, sheets, discs, filter tubes, and welded screens

- Operating Temperature: Up to 600°C

We offer custom mesh cutting and shaping for cartridge inserts, reactor linings, and process screens.

Case Study: Titanium Mesh in Bromine Recovery Unit

A specialty chemicals company faced corrosion failures with 316 SS filters in their bromine recovery loop.

Solution:

- Replaced with Titanium Grade 2 mesh (40 mesh, 0.3 mm wire)

- Installed as disc filters in acid stream piping

- Result: 0 corrosion after 6 months, with stable throughput and zero contamination

✅ ROI: Extended filter lifespan 3x, reduced downtime by 50%

Titanium vs Stainless Steel & Nickel Alloys

| Property | Titanium Wire Mesh | SS 316 Mesh | Hastelloy / Nickel Mesh |

|---|---|---|---|

| Corrosion Resistance | Outstanding (oxidizers + chlorides) | Very good, but not in halides | Excellent in reducing acids |

| Weight | Lightweight | Heavier | Heavy |

| Thermal Stability | Up to 600°C | ~700°C | ~850°C |

| Reactivity | Non-reactive | Reactive in some acid blends | Non-reactive |

| Cost | Premium | Moderate | High (varies by grade) |

| Best For | Chloride-rich, high-purity systems | General chemical processing | Reducing acid applications |

🔗 Compare with 316 SS Welded Mesh

🔗 Explore 304 SS Mesh

🔗 See Full Stainless Steel Mesh Range

Why Choose IG Wire Screen for Titanium Mesh?

- ✅ Titanium mesh in stock for chemical industries

- ✅ Precision cutting & shaping for filters, trays, strainers, and baffles

- ✅ Chemical compatibility guidance from technical engineers

- ✅ Export-ready packaging + documentation

- ✅ Serving India and global chemical OEMs since 1980s

When your process is critical and corrosion is costly, we deliver the right titanium mesh solution—on time, to spec.

Supply Capability & Global Reach

At IG Wire Screen Co., we support chemical OEMs, EPC contractors, and industrial end-users with:

- ✅ Titanium mesh in multiple grades and mesh sizes

- ✅ Custom fabrication: discs, cones, welded screens

- ✅ Export-grade packaging for coastal and high-humidity environments

- ✅ Documentation: mill test certificates, chemical resistance data, HS code labels

- ✅ Prompt delivery within India and internationally

We serve critical plants where safety, uptime, and chemical compatibility can’t be compromised.

Buyer Tips for Choosing Titanium Mesh

✔️ For chlorine, bleach, and bromine lines, use Grade 2 mesh

✔️ For high-pressure or high-strength applications, choose Grade 5 (Ti-6Al-4V)

✔️ Opt for plain weave for general filtration; Dutch weave for fine separation

✔️ Confirm process temperature and chemical compatibility before selecting mesh

✔️ Always request mesh count + wire diameter based on flow rate and particle size

→ Talk to Our Mesh Engineer for Free Consultation

🔍 Voice Search Optimized FAQs

Q1. What is titanium wire mesh used for in chemical plants?

It’s used for filtration, separation, and corrosion-resistant containment in aggressive chemical environments.

Q2. Is titanium mesh better than stainless steel for corrosive chemicals?

Yes. Titanium outperforms stainless steel in chloride, bromine, and high-purity acidic conditions.

Q3. What titanium grades are available in mesh form?

We supply both Grade 2 (CP Titanium) and Grade 5 (Ti-6Al-4V) in multiple mesh sizes.

Q4. Can titanium mesh be welded or formed into custom shapes?

Yes. We offer cutting, forming, and welding services for baskets, discs, or frame assemblies.

Q5. What mesh sizes are commonly used in chemical filtration?

Mesh sizes range from 4 to 150, depending on application — fine filtration, debris screening, or pressure flow.

Q6. How does titanium handle temperature in chemical processes?

It remains stable up to 600°C and resists thermal oxidation in most chemical media.

Q7. Do you provide documentation with titanium mesh supply?

Yes. We include mill test certificates, compliance docs, and corrosion data with all orders.

Q8. Where can I buy titanium wire mesh in India or for export?

You can buy directly from IG Wire Screen Co. — we ship globally with custom cut and fabrication services.

📢 Call to Action – Engineered for Harsh Chemistry

Your plant doesn’t run on second-best materials.

Choose titanium mesh for unmatched corrosion resistance, strength, and long-term reliability — in every drop of acid, every cycle of heat.

🧾 Request a Custom Quote or Spec Sheet

📥 Download Chemical Compatibility Chart

🔧 Talk to Our Mesh Experts for Engineering Support

→ Contact IG Wire Screen Co. Now

🧠 Final Takeaway: Built for Chemistry, Backed by Experience

Titanium mesh is not just corrosion-resistant — it’s chemically smart, structurally strong, and industrially reliable.

When failure isn’t an option, Titanium delivers durability, purity, and peace of mind.