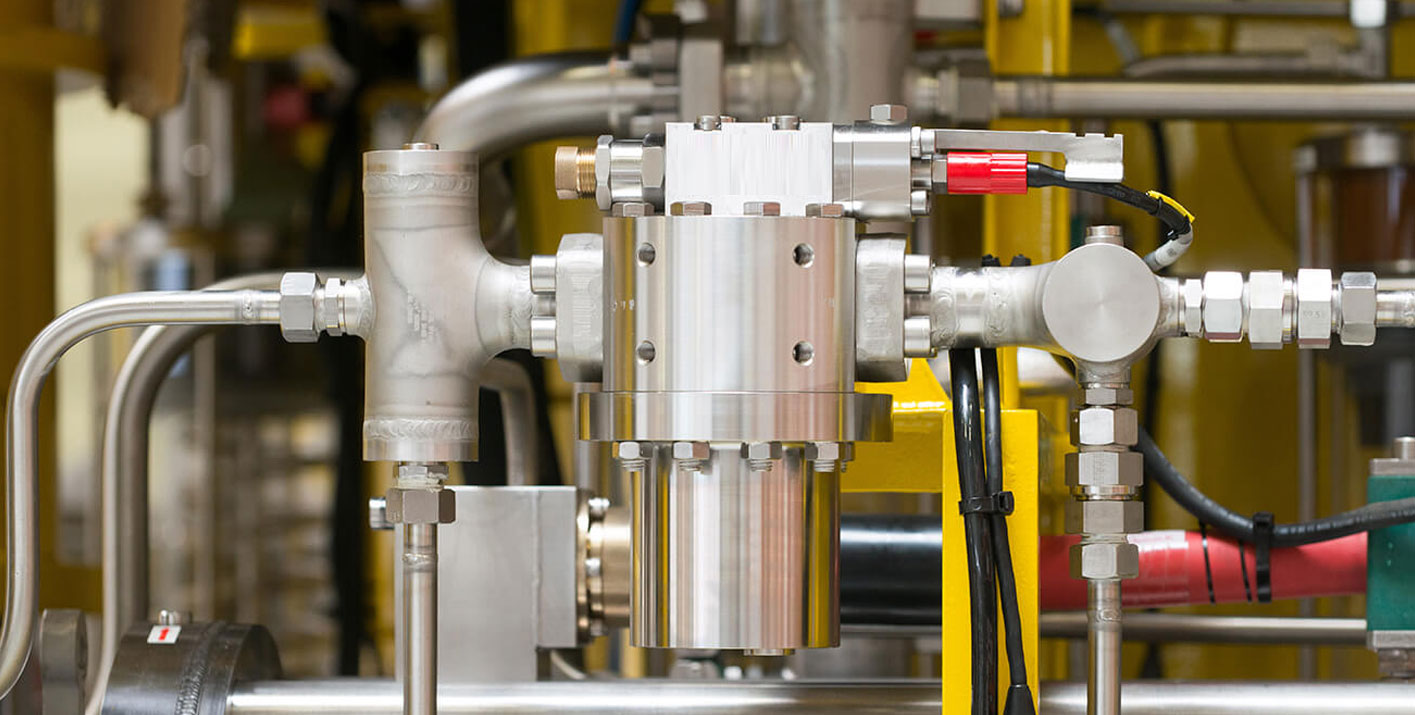

An Essential component for your Hydraulic system.

Introduction to Hydraulic Filters

Hydraulic system mechanisms will only work properly if the fluid contained in the system is clean and uncontaminated. Dirt or other contaminants such as sludge, oxidation, metal, sand, shredded elastomeric seals or chemical by-products can come into the system and cause corrosion to the components. Contamination can severely affect the chemical and physical nature of hydraulic fluids, leading to system inefficiency. This failure in efficiency can result in malfunctioning equipment, expensive downtime and needless repairs to damaged parts.

Preventing these harmful particles from entering or continuing in your hydraulic system is vital to your equipment’s victory and durability. This guide to hydraulic filters will help you determine which kind of hydraulic filter is correct for your machines.

What are Hydraulic Filters?

A hydraulic filter is a component inside a hydraulic system that eliminates damaging particulates by forcing hydraulic fluid through an absorbent filter element. The filter element catches contaminants and stops them from re-entering the fluid flow and damaging other pieces of equipment further downstream. Pollutants range from dirt to water and reactive chemicals. Their extent is on a scale of micrometres, meaning hydraulic filters must be correctly sized to filter out even the smallest of particles.

In a hydraulic system, hydraulic fluid achieves four essential responsibilities:

- Transfers energy: The motion of the liquid through the system generates pressure used during system operation. Dirt can plug minor orifices in flow control and pressure valves. Clogged valves stop pressure from escaping, potentially resulting in a reduced efficiency, unnecessary maintenance and interruption.

- Seals spaces between metal parts: Fluid seals the small cavities between close-fitting components, acting as a pressurized barricade to contaminants. Damaging particles cannot break this seal. However, dirt can plug holes if the seal breaks.

- Lubricates inner components: Silting is the procedure by which extremely fine particles of dirt become trapped in clearances, hindering the lubrication of moving parts. Large contaminants can cause the same problem. Poorly lubricated components wear down extremely and are unreliable.

Cools system components: Hydraulic fluid produces heat during the system operation procedure through friction. The heat is usually transferred to the walls of the reservoir when the fluid returns from its circuit. Contaminants can produce a sludge on the walls of the tank that stops heat transfer. Efficient hydraulic systems operate at a cooler temperature.

Functions of Hydraulic Filters

The function of a hydraulic filter is to eliminate contaminants at a particular stage of system operation. There are numerous ways contaminants can enter a system:

- Environmental: Some pollutants accumulate during the manufacturing procedure of the hydraulic system. Wreckage like paint chips, rubber particles and metal shavings can collect in the system. An air hose may blow these pollutants away, but others are too small to be seen and must be filtered out. A huge amount of contamination also enters the system in new fluid. Fluid already in a system is normally cleaner than any new fluid that you will add; new oil is not necessarily clean, typically 22/20/18. Therefore, you should follow good filtration practice and use a filter cart or pre-filtered fluid every time you add fluid to keep it inside cleanliness level specification. It would help to filter fluid before adding it to a hydraulic system and several times throughout operation.

- System-generated: The inner parts of a system, like piston rods and pumps, create contaminants during routine procedures. Return-line filters are proficient at collecting this kind of contaminant. Castings also wear down due to shock pressures and repeated flexing and can then enter the fluid stream.

External: Air can sometimes enter the system through breather caps, imperfect seals or other openings, reducing on the system’s walls and leading to rust. It is critical to clean breather caps, as dirt ultimately gets back into the fluid. Maintenance authorities also introduce new particles when replacing parts.

Benefits of Hydraulic Filters

Hydraulic filters extend the life of your hydraulic system and its components significantly. Filters sustain an impurity-free fluid by limiting the consumption of contaminants and swiftly eliminating new ones.

Hydraulic filters also defend components from failure triggered by the build-up of particles between close-fitting parts or lubricated mechanisms. Protection from wear and tear decreases the chance of malfunction and keeps systems safer.

An efficient, well-placed filter also saves your money and downtime due to expensive replacements or repairs. Ensuring your hydraulic filter suits your equipment’s needs the first time around will extend its life and allow you to work more efficiently.

Hydraulic Filter Applications

Because hydraulic systems can function with fluids or gases, various industries use them in production and manufacturing. Hydraulic power is involved in agriculture, aerospace and aviation, military and defence, chemical processing and industrial automation, among many other fields.

Modern aircraft use hydraulic systems to trigger controls and deploy their landing gear. Missiles and their ground-support equipment both use fluid power. Vehicles use hydraulic power in their braking, steering and transmission mechanisms. Farm equipment like combines and tractors rely on hydraulics, as well.

Conclusion

We at Indo German Wire Screen Co., manufactures and supplies Stainless Steel Wire Mesh for various industrial and commercial applications. Our Stainless Steel Wire Mesh is dimensionally precise for Hydraulic Filters and destined for lessening the down time of filtration significantly, due to its mesh size. At Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.