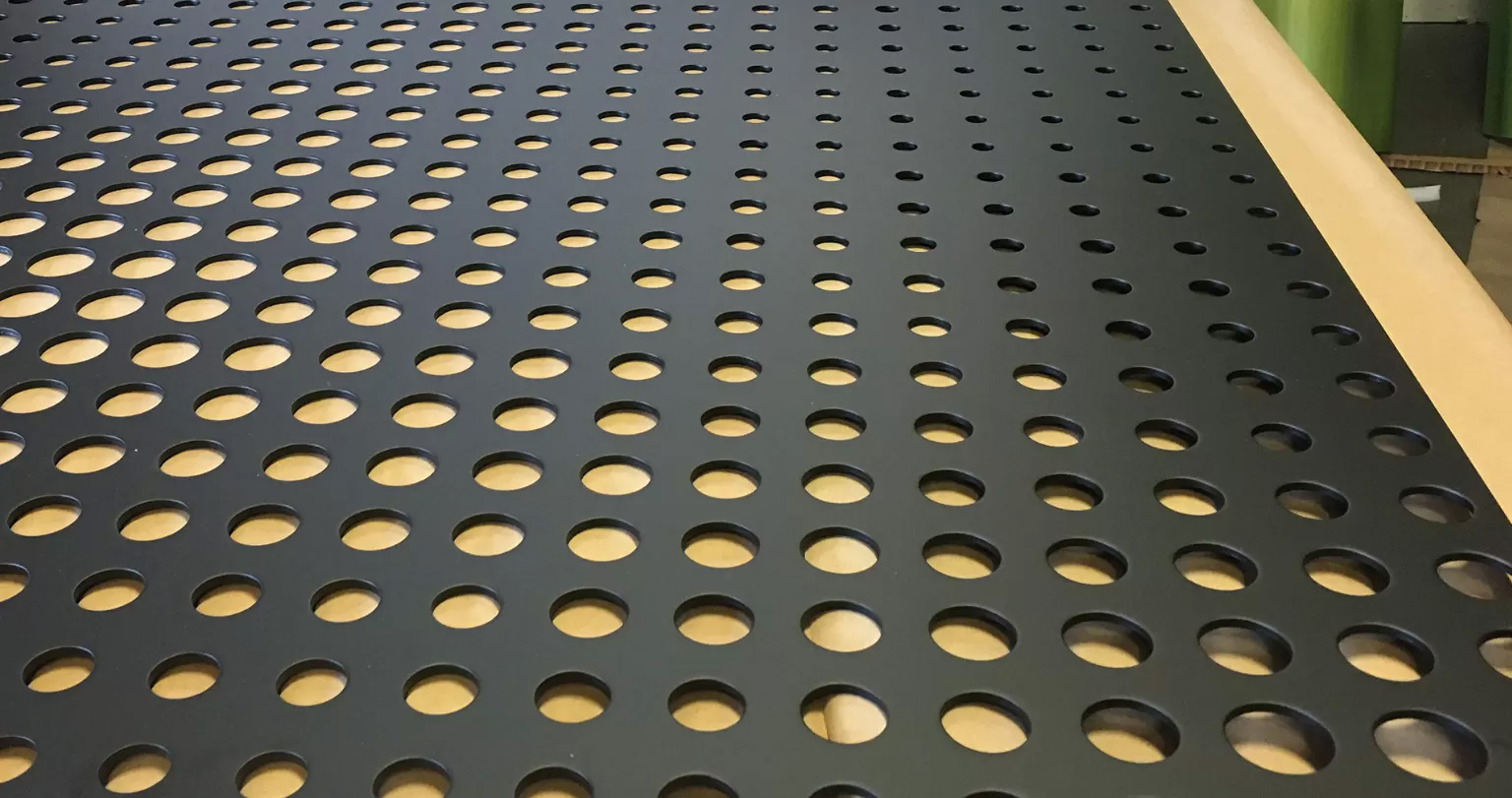

The most popular perforated sheet pattern used in modern times.

What is Perforated Sheet

A metal sheet is said to be perforated if it has been punched or stamped manually or automatically using CNC or laser-cutting technology to create different patterns or holes in it of different shapes and dimensions. Some of the most common materials that are used to manufacture Perforated Sheets are aluminum, galvanized iron, and stainless steel. It is also known as a perforated metal screen or plate. Perforated Sheets are lighter in weight and deliver good grip and passage of liquid through them.

Most Common Patterns of Perforated Sheet

Honeycomb Design:

This design is extensively used for several indoor and outdoor applications. Honeycomb Design Perforated Sheet are used to make privacy screens, facades, window nets, fences, etc. The honeycomb-patterned sheets are extremely versatile.

Grids and Squares:

This is a repetitive pattern with an appealing look. Grids and Squares Perforated Sheet is not entirely restricted to square shaped grids but can also be rectangular or in any other shape.

Mesh Pattern:

The mesh pattern contains small holes gathered close together. It has fine and complex detailing. Mesh patterns can be very useful to manipulate sunlight exposure. They are also used as privacy screens and window nettings. The size of the mesh can be modified.

Herringbone Design:

This is a prevalent upcoming pattern used in a wide range of applications. Herringbone Design has a classic and beautiful look with fashionable finishing. It is a trending design seen commonly as sunscreens. The herringbone design has also been embraced by the fashion industry. Soles of shoes and sneakers have this design. It has a zig-zag rhombus type design which is very visually pleasing with neat designs.

What are the criteria to choose a particular pattern?

There are 3 major characteristics one needs to consider while choosing a suitable patterned sheet: Hole size, Open area and hole geometry.

The Hole Size decides the size of particles that can pass through the sheet. They manipulate the penetrability of the metal sheet. The see-through capability of the sheet is also determined by the hole size.

The Open Area is an indication of how much metal is absent after the cutting procedure. It directly affects the weight of the sheet. The Open Area determines the quantity of air or liquid that can pass through the sheet.

Hole Geometry comprises of three main kinds of sheets. One can choose from square holes, round holes, and designer patterns, each symmetrical shape has a unique purpose.

Applications

Perforated sheets are used in a wide range of sectors, including architecture and construction, among others. Here are some examples:

- Perforated sheets are frequently used in architecture as fence screens, column coverings, sunshades in gardens, cladding, and more.

- Perforated sheets are used as ventilation grids, acoustic panels to reduce noise, signboards, pipe guards, and other applications.

- Perforated sheets are used in tractors for engine aeration, air filters, radiator grills, bike silencers, oil filters, and other applications.

- Perforated sheets are utilized in an extensive range of applications, including mine cages, filters, battery separator plates, water screens, and gas purifiers.

As a result, perforated sheets have an extensive range of applications and may be used in different ways. If you want a manufactured perforated sheet for your application, we make sure you get the suitable size and material from us.

Conclusion

At Indo German Wire Screen Co., we have sufficient manpower and the great minds on board that enables us to provide the critical perforation jobs for our most valuable customers. The goal of reaching an encompass-able level of customer satisfaction has enhanced the competency and quality of production with every innovation. One can truly realize the importance of perforated sheets by exploring possibilities with Indo German Wire Screen Co. professionals whose years of experience in the field have resulted in a creation of a wide range of products in a huge bracket of sectors across the world.