Welcome to our comprehensive guide on square hole perforated sheets, where precision meets versatility. Choosing the right thickness and hole size is crucial for ensuring optimal performance in various applications. With the expertise of Indo German Wire Screen Co., a leading name in perforated sheets, we’ll unravel the intricacies of material selection.

Understanding Square Hole Perforated Sheets

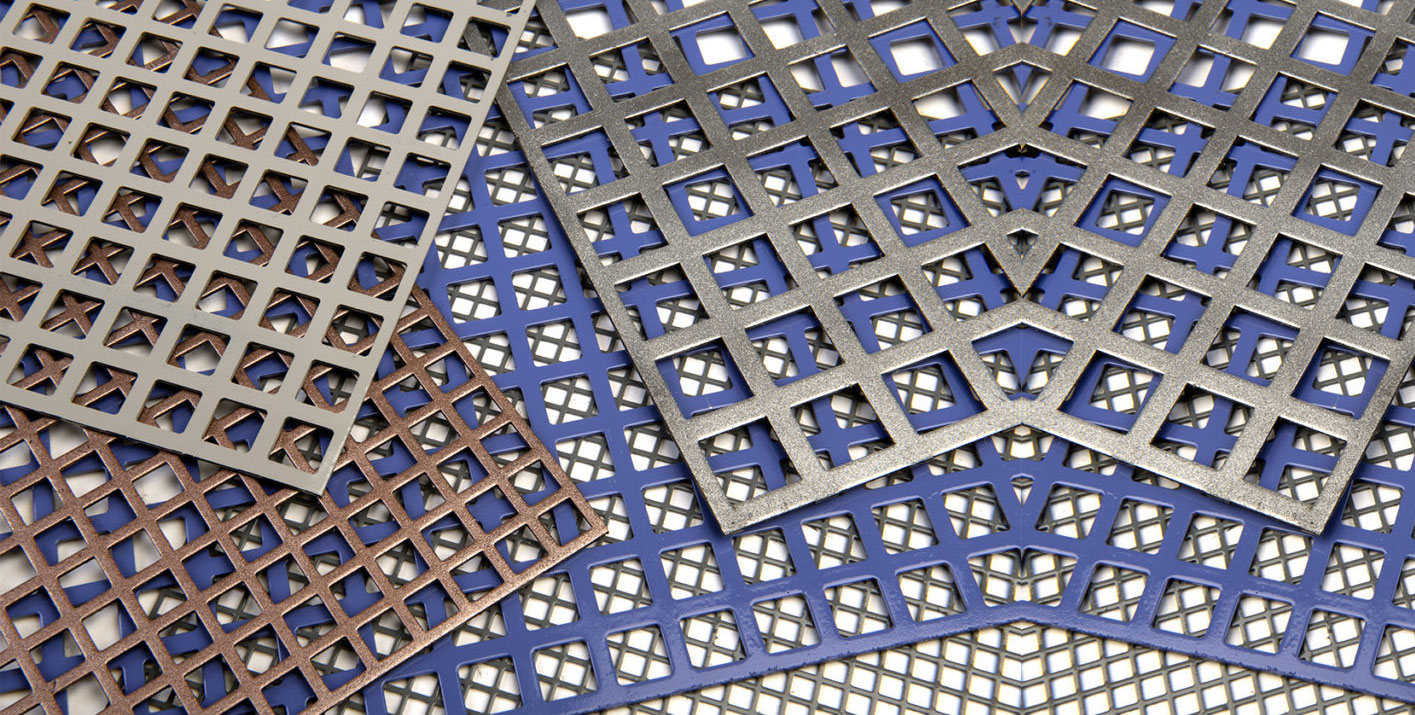

Square Hole Perforated Sheets are a specialized form of perforated metal, distinguished by their precisely punched square-shaped holes. These sheets find extensive use in various industries due to their unique design and functional benefits. Square Hole Perforated Sheets are metal sheets that feature a pattern of perfectly aligned square holes. This distinctive hole shape sets them apart from other perforated sheets and plays a crucial role in determining their applications and performance.

The square hole pattern offers several advantages in specific applications. Its geometric design allows for efficient airflow, making it ideal for applications that require ventilation or filtration. Additionally, the square shape provides enhanced structural integrity, making these sheets suitable for projects that require strength and durability. Square Hole Perforated Sheets are favoured in architectural and industrial settings for their aesthetic appeal and functional benefits. Understanding these advantages allows for informed decision-making when considering perforated sheet options for a project.

Square Hole Perforated Sheets vs. Other Patterns

When it comes to perforated sheets, the choice of hole pattern is a critical consideration. Square hole perforated sheets offer distinct advantages compared to other patterns. Their geometric symmetry provides efficient airflow and structural integrity, making them ideal for applications requiring ventilation or filtration. In contrast, other patterns like round holes may have specific benefits in different contexts. Understanding the unique advantages of square hole patterns empowers decision-makers to select the most suitable perforated sheet for their specific project requirements.

Applications of Square Hole Perforated Sheets Across Industries

Square Hole Perforated Sheets find extensive use in a wide array of industries due to their versatile nature and unique benefits. Here’s a closer look at some key sectors where they play a pivotal role:

Architectural Marvels: Enhancing Aesthetics with Square Hole Perforated Sheets

In the realm of architecture, square hole perforated sheets serve as dynamic design elements. Their geometric patterns lend a modern and sophisticated aesthetic to facades, interior spaces, and decorative elements. These sheets enable architects to achieve a delicate balance between form and function, creating visually striking structures that also offer practical benefits.

Industrial Utilities: Efficiency and Functionality in Every Hole

In industrial settings, the efficiency of operations is paramount. Square hole perforated sheets are instrumental in processes that require precise airflow or filtration. They find applications in machinery, equipment enclosures, and ventilation systems, ensuring optimal performance and safeguarding against contaminants. Their robust construction also contributes to the durability and reliability of industrial equipment.

Agricultural Advancements: A Closer Look at Perforated Sheets

The agricultural sector benefits significantly from the versatility of square hole perforated sheets. These sheets are used in tasks ranging from grain drying and sorting to animal confinement and ventilation. The precise hole patterns facilitate processes crucial to modern agricultural practices, enhancing productivity and efficiency on the farm.

In each of these industries, square hole perforated sheets prove themselves as invaluable components, offering a combination of aesthetic appeal, functionality, and durability. Their adaptability to diverse applications showcases their importance as a versatile material in modern engineering and design.

Choosing the Right Thickness and Hole Size

Selecting the appropriate material thickness and hole size is a critical step in ensuring the optimal performance of square hole perforated sheets, and Indo German Wire Screen Co. stands ready to assist in this endeavour.

Impact of Material Thickness on Strength and Performance: The thickness of the perforated sheet material plays a pivotal role in determining its overall strength and durability. Indo German Wire Screen Co. provides a diverse range of thickness options tailored to meet various application needs. For heavy-duty applications that demand robustness, opting for a thicker material ensures longevity and structural integrity. Conversely, in situations where weight considerations or flexibility are crucial, a thinner material may be the preferred choice. Indo German’s expert guidance ensures that clients make informed decisions based on their specific project requirements.

Hole Size Considerations: Striking the Perfect Balance: The size of the holes in a perforated sheet is equally significant. Indo German Wire Screen Co. offers a range of hole sizes designed to strike the perfect balance between functionality and aesthetics. Larger holes provide efficient airflow and filtration, making them suitable for applications like ventilation systems. Smaller holes, on the other hand, offer enhanced structural integrity, making them ideal for projects that require strength and durability. With Indo German’s extensive experience, clients can be confident in selecting the most appropriate hole size to achieve the desired outcome for their project.

By considering the impact of material thickness and hole size clients can confidently choose square hole perforated sheets that align precisely with their project requirements, ensuring optimal performance and longevity.